-

The forum has been upgraded to support both light and dark themes. Click here for directions.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Restoring my fathers old hunting Jeep

- Thread starter JohnL48

- Start date

JohnL48

Well-Known Member

For what to pull out your broken Kubota ? ;-)Rescue Jeep needs a winch in the front

CTM1

Active Member

For what to pull out your broken Kubota ? ;-)

You got me this that one, but thankfully the Evil Orange is up and running better then ever. A buddy of mine whois a master electrician traced the issues out and fixed them.

Last edited:

Dennis Duffy

Active Member

I agree with all the comments!! I love this thread and it amazes me. Mainly because I am the worst when it comes to any kind of work on vehicles. Give me a hammer and nails and I am right at home LOL! Beautiful work! It was so cool to watch that jeep transform! And can't wait to see the finished project on the older jeep!

JohnL48

Well-Known Member

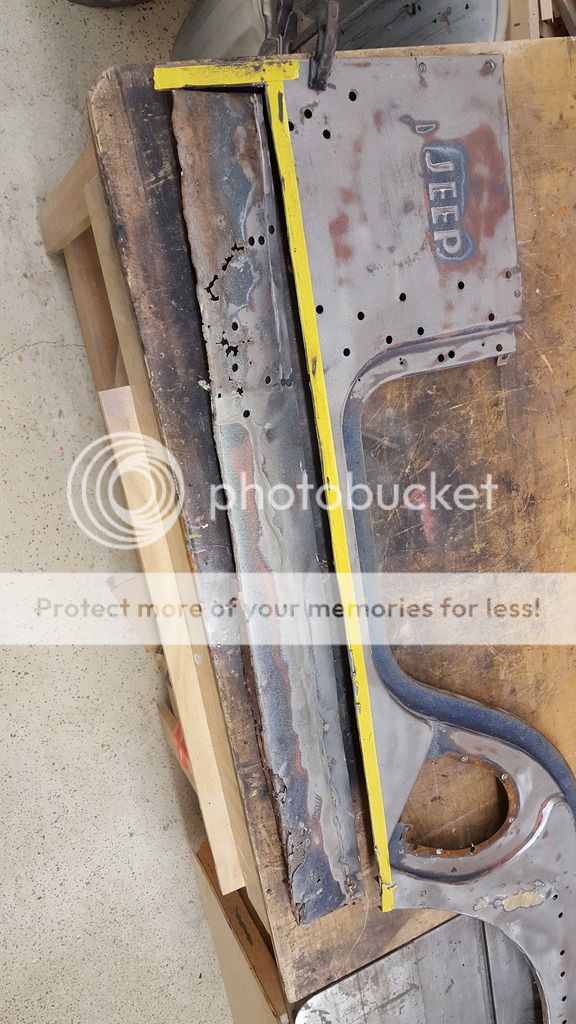

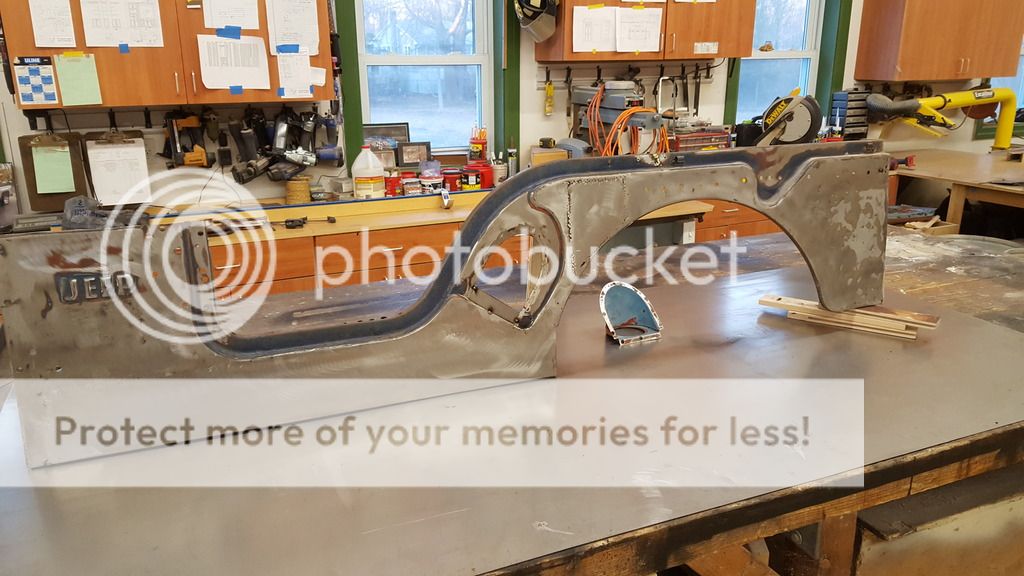

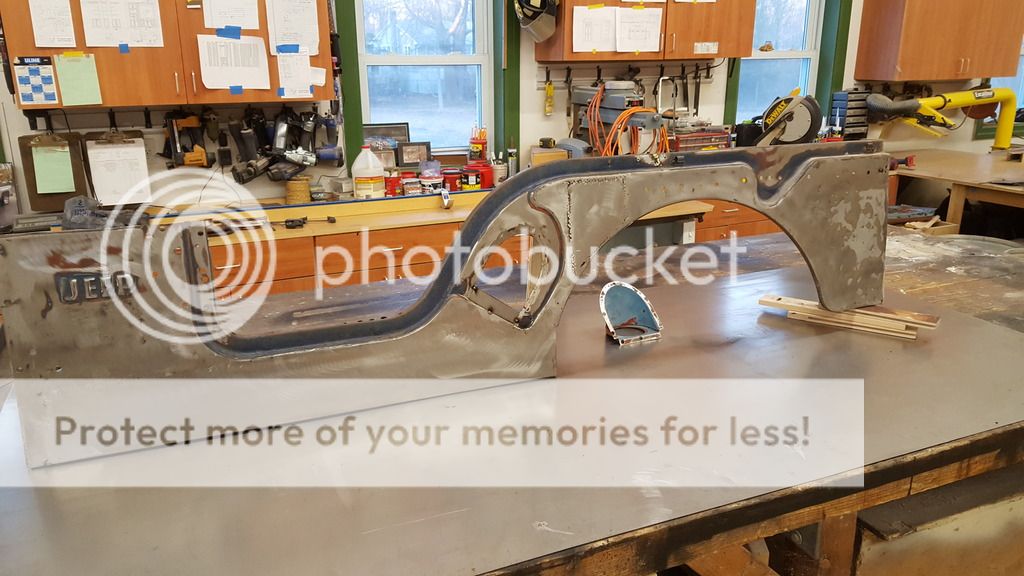

Ready for surgery

Just used a jig saw for the cut, the grinder freaks out the dog

Don't want to interrupt the princess

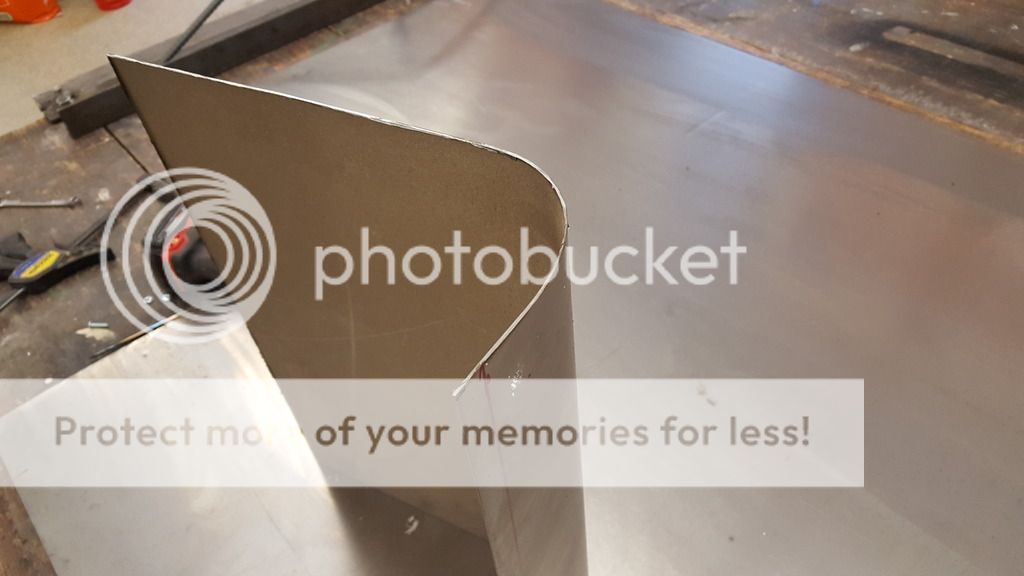

Using the home made brake for the first time, the angle iron that holds the handle flexed too much and wouldn't bend the middle of the pc so I need to work on that, but hammer fixes everything

Enough for tonight. More coming tomorrow

Just used a jig saw for the cut, the grinder freaks out the dog

Don't want to interrupt the princess

Using the home made brake for the first time, the angle iron that holds the handle flexed too much and wouldn't bend the middle of the pc so I need to work on that, but hammer fixes everything

Enough for tonight. More coming tomorrow

JohnL48

Well-Known Member

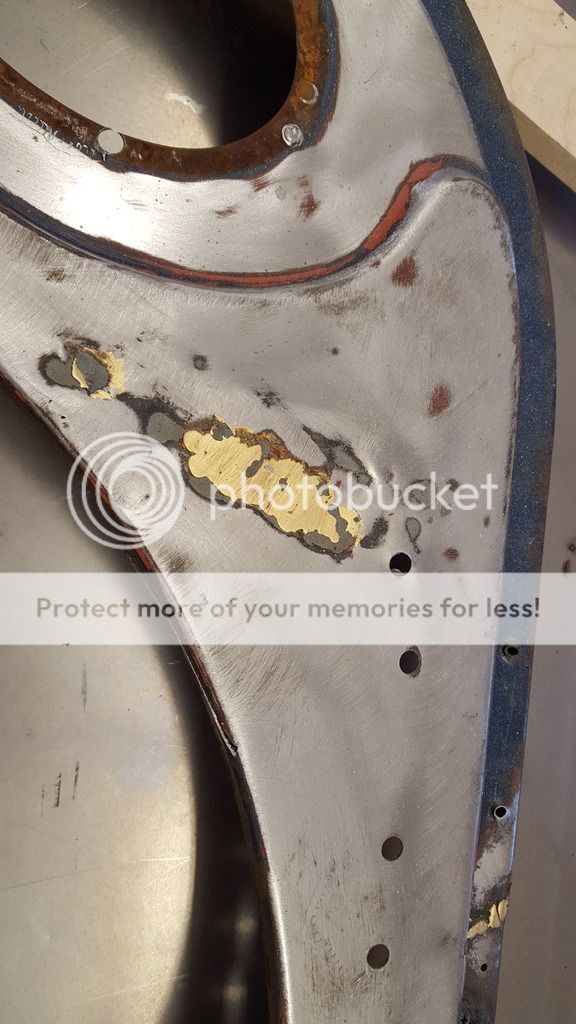

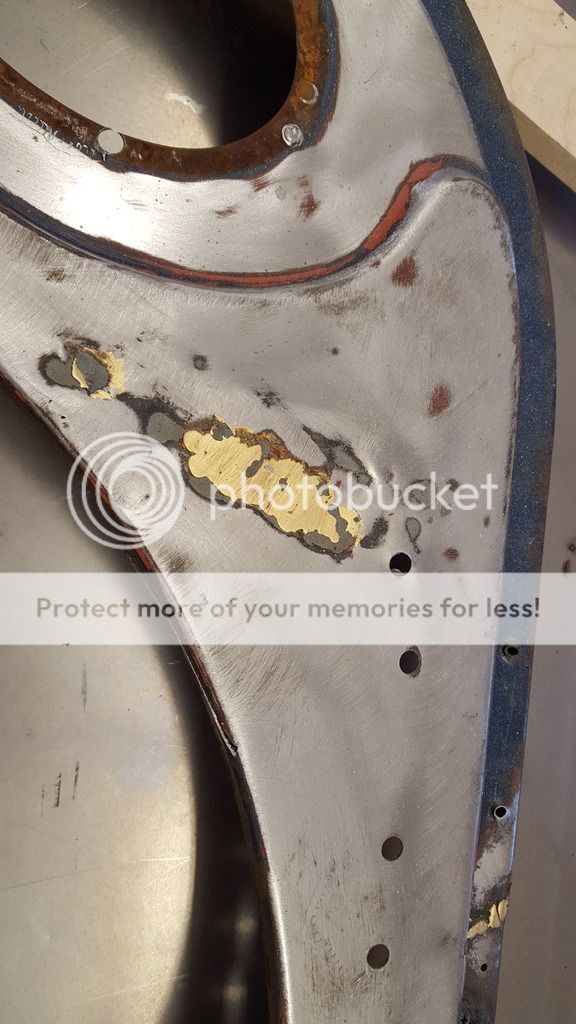

Some progress today.Had some gaps to fill so a copper tee was sacrificed

Worked pretty dang good

The holes you see are just spot welds. no need to fill them since I will need them later

time to fix this spot

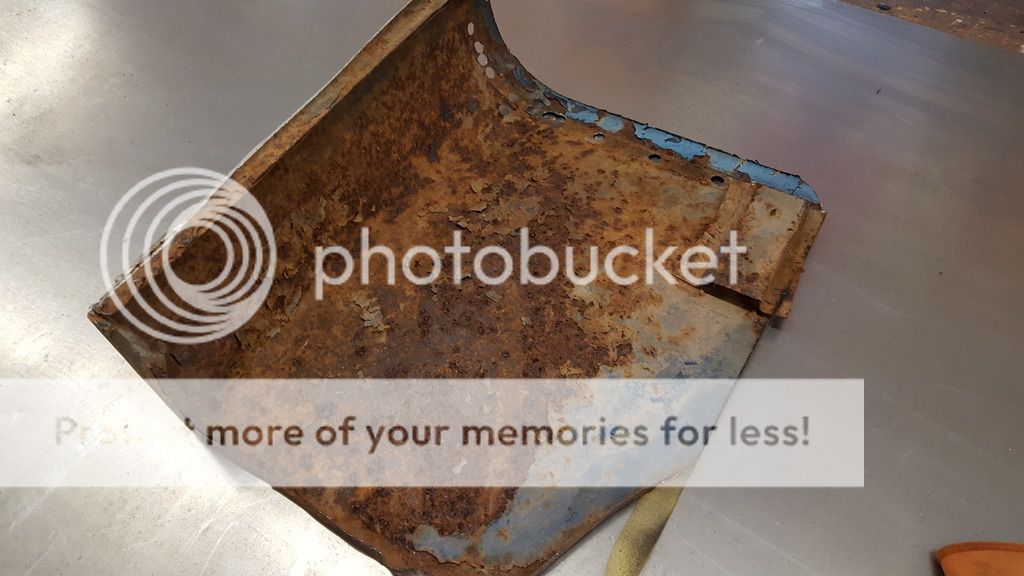

The pc removed was pretty rusty

Grind weld, grind weld, grind weld fun fun

Worked pretty dang good

The holes you see are just spot welds. no need to fill them since I will need them later

time to fix this spot

The pc removed was pretty rusty

Grind weld, grind weld, grind weld fun fun

JohnL48

Well-Known Member

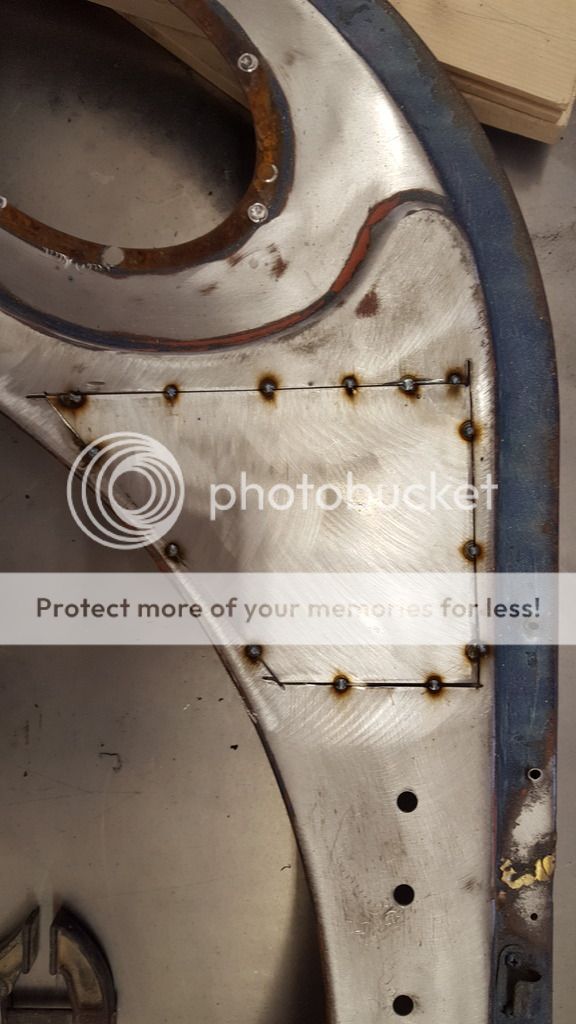

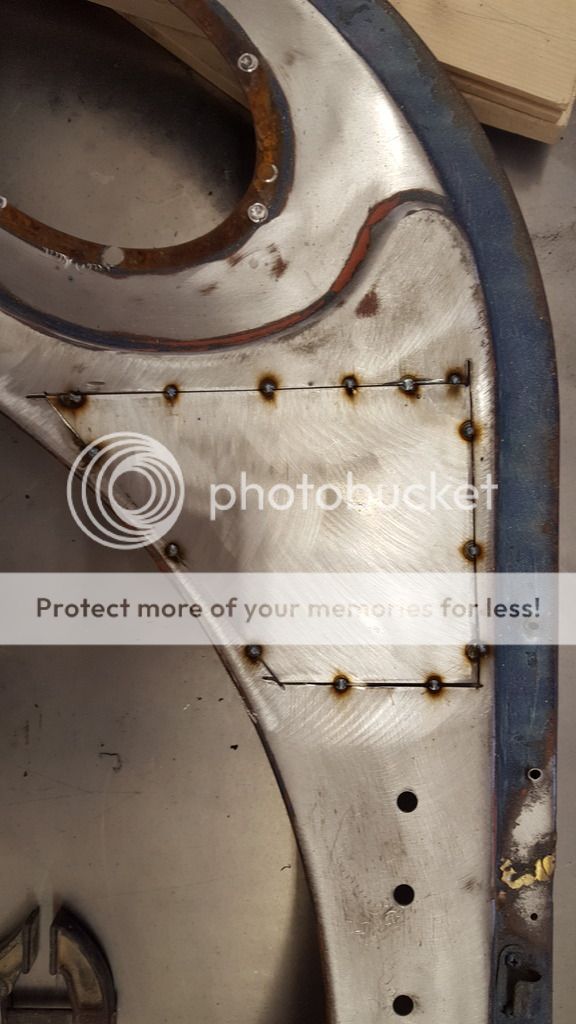

SO, word of advice !! when you plan on welding all weekend DON'T leave your argon tank on all night, especially on a holiday. It WILL be empty by morning. grrrrrrr so I guess I'll get to work on this spot for now

I got this pc from a fine member on another forum

Can only tack it cuz I'M OUT OF GAS

Where I'm at now

I got this pc from a fine member on another forum

Can only tack it cuz I'M OUT OF GAS

Where I'm at now

JohnL48

Well-Known Member

So what have I learned ?? Keep in mind I am new to this welding stuff.

Make sure when you are welding that the patch stays flush with the original panel, check it often

Weld some grind some. If you do all the welding then grind you WILL lose your mind

Just grind off the heads of the weld, try not to hit the sheet metal, it will get so thin you will cut the patch off and start over, Please don't ask how I know this !!

I use a 4.5" grinder with a 1/16" cutting disk turned 90 degrees from the weld. Then I just nibble at the weld until flush, then I hit it with a flap wheel and start again

The more you try to get it perfect the worse it gets, A thin coat of filler, block sanded works wonders

Use copper behind wider gaps it works wonders

Heat from grinding also warps, keep a hammer handy to flatten and used compressed air to cool often

Grinding makes your shop dirty

DON'T FORGET TO TURN YOUR GAS OFF WHEN DONE

Make sure when you are welding that the patch stays flush with the original panel, check it often

Weld some grind some. If you do all the welding then grind you WILL lose your mind

Just grind off the heads of the weld, try not to hit the sheet metal, it will get so thin you will cut the patch off and start over, Please don't ask how I know this !!

I use a 4.5" grinder with a 1/16" cutting disk turned 90 degrees from the weld. Then I just nibble at the weld until flush, then I hit it with a flap wheel and start again

The more you try to get it perfect the worse it gets, A thin coat of filler, block sanded works wonders

Use copper behind wider gaps it works wonders

Heat from grinding also warps, keep a hammer handy to flatten and used compressed air to cool often

Grinding makes your shop dirty

DON'T FORGET TO TURN YOUR GAS OFF WHEN DONE

Tenured Student

Active Member

This is truly one my favorite threads. If I attempted a similar project it would be equivalent to me sitting in a rocking chair- it would give me something to do but I would never get anywhere with it.

Sent from my iPhone using Deer Hunter Forum

Sent from my iPhone using Deer Hunter Forum

Similar threads

- Replies

- 0

- Views

- 5K

- Replies

- 5

- Views

- 2K