yoderjac

Well-Known Member

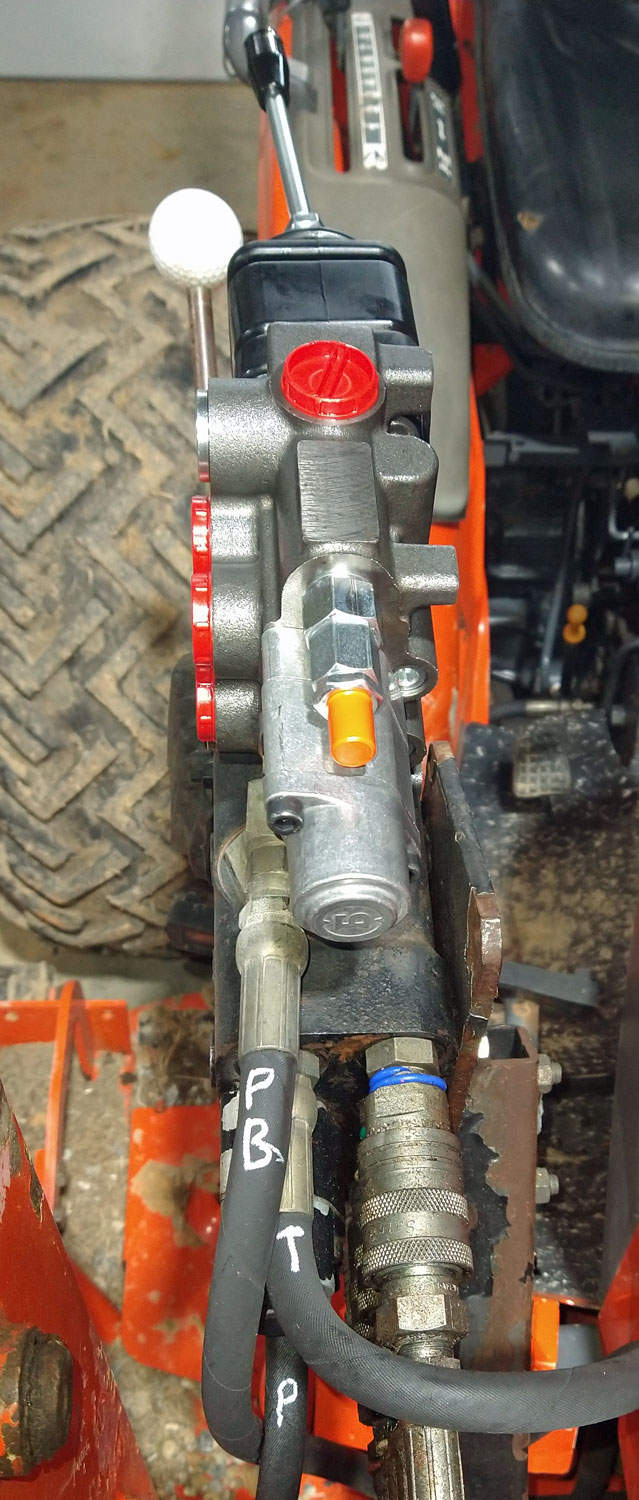

I have an old B2400 with a belly mower that I used the the burbs for lawn care and snow removal. It has an aftermarket SMC 64 loader. The loader valve does not have float.

As I retire, I will have a concrete slab in front of the new garage (for my wife, it is a pickleball court). I had to play with the joystick for loader height adjustment on the fly since it doesn't have float, but I was not concerned about scratching the asphalt driveway. The new place will be cement and I'd like to be a bit more careful. I plan to get a clamp on type snow blade for the cutting edge of the bucket. It is only a couple hundred bucks. I'd still like to have a float function on the bucket.

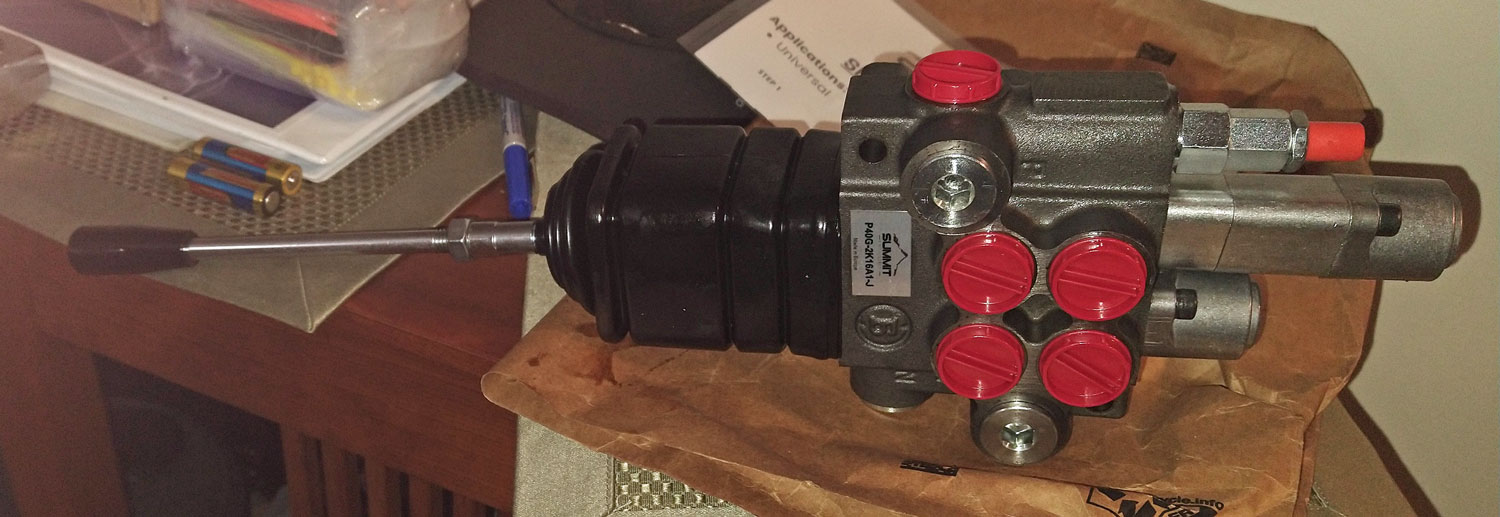

The loader joystick and valve are pretty old. The rubber sleeve is torn and sometimes the control sticks a bit. So I'm considering replacing it with one that has float. I am a novice when it comes to hydraulics. The B2400 has open center hydraulics. I'm looking at this valve with float: https://summit-hydraulics.com/produ...onal-control-valve-w-joystick-2-spool-11-gpm/

It has more flow than the B2400 can produce. I'm thinking it should be pretty much a one for one swap. I presume I can use the quick connects and adapters from the current valve. This one has a power beyond option, but for the life of me I can't think of a use for rear hydraulics on a tractor this small. Here is the clamp on snow blade I'm looking at: https://www.ratchetrake.com/

Before I put out the money for a new valve, I'd like you guys who know hydraulics inside and out to make sure I'm not doing anything stupid here or missing something. If anyone has used the snow edge I'd like to hear about that.

I'm in no rush as the garage and house have not yet been build let alone the pickleball court poured. It will be next winter before I'll actually use this. To be honest, I'm getting a knee replaced later this month and I'm also looking for a cure for cabin fever when I can hobble around but am not fully functional during the recovering period.

Thanks in advance!

As I retire, I will have a concrete slab in front of the new garage (for my wife, it is a pickleball court). I had to play with the joystick for loader height adjustment on the fly since it doesn't have float, but I was not concerned about scratching the asphalt driveway. The new place will be cement and I'd like to be a bit more careful. I plan to get a clamp on type snow blade for the cutting edge of the bucket. It is only a couple hundred bucks. I'd still like to have a float function on the bucket.

The loader joystick and valve are pretty old. The rubber sleeve is torn and sometimes the control sticks a bit. So I'm considering replacing it with one that has float. I am a novice when it comes to hydraulics. The B2400 has open center hydraulics. I'm looking at this valve with float: https://summit-hydraulics.com/produ...onal-control-valve-w-joystick-2-spool-11-gpm/

It has more flow than the B2400 can produce. I'm thinking it should be pretty much a one for one swap. I presume I can use the quick connects and adapters from the current valve. This one has a power beyond option, but for the life of me I can't think of a use for rear hydraulics on a tractor this small. Here is the clamp on snow blade I'm looking at: https://www.ratchetrake.com/

Before I put out the money for a new valve, I'd like you guys who know hydraulics inside and out to make sure I'm not doing anything stupid here or missing something. If anyone has used the snow edge I'd like to hear about that.

I'm in no rush as the garage and house have not yet been build let alone the pickleball court poured. It will be next winter before I'll actually use this. To be honest, I'm getting a knee replaced later this month and I'm also looking for a cure for cabin fever when I can hobble around but am not fully functional during the recovering period.

Thanks in advance!