-

The forum has been upgraded to support both light and dark themes. Click here for directions.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Ultimate Deer Skinning Hoist

- Thread starter Mennoniteman

- Start date

Mennoniteman

Well-Known Member

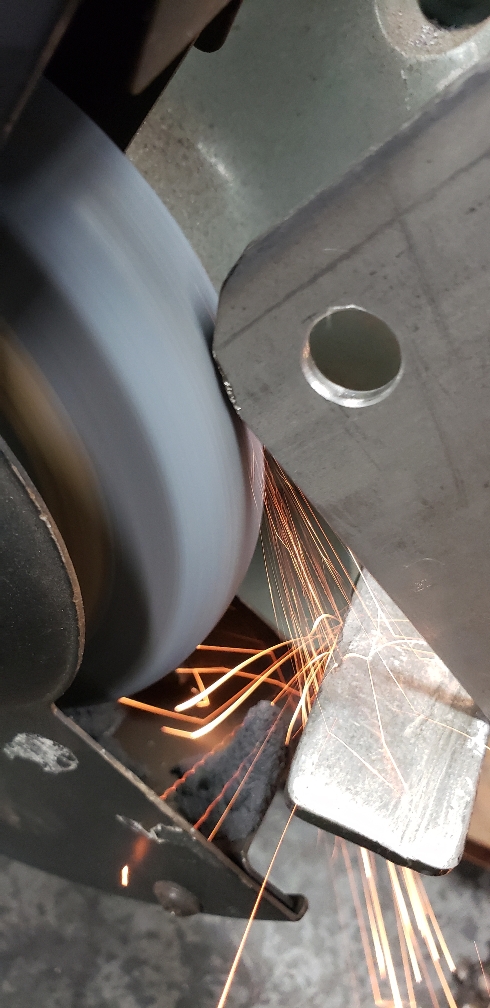

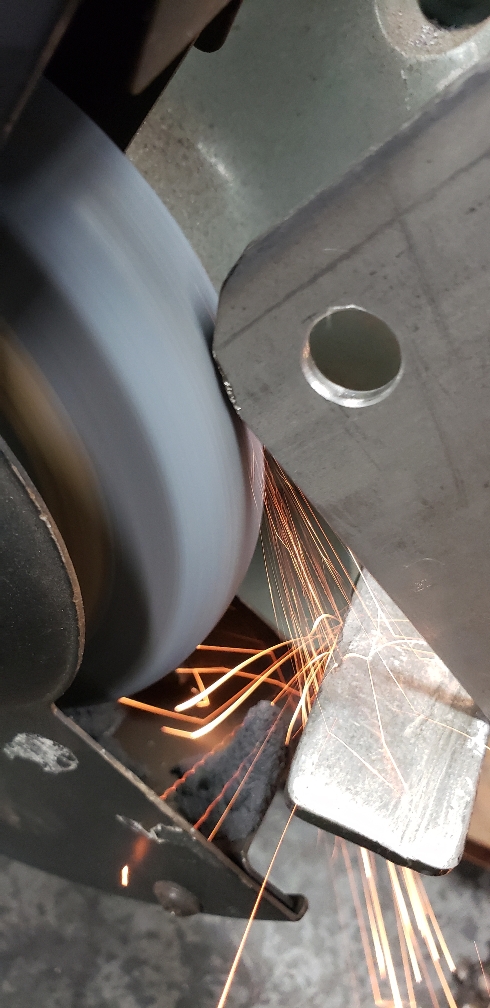

Making a few parts for the winch.

Mennoniteman

Well-Known Member

For starters I bought a Titan 1/2 TON ADJUSTABLE STEEL GANTRY CRANE SHOP LIFT for $498.97. I know that this sounds expensive for a deer butchering hoist, but I can use this lift for other things such as working on my zero turn.

https://www.palletforks.com/industr...able-steel-gantry-crane-shop-lift/840041.html

https://www.palletforks.com/industr...able-steel-gantry-crane-shop-lift/840041.html

Mennoniteman

Well-Known Member

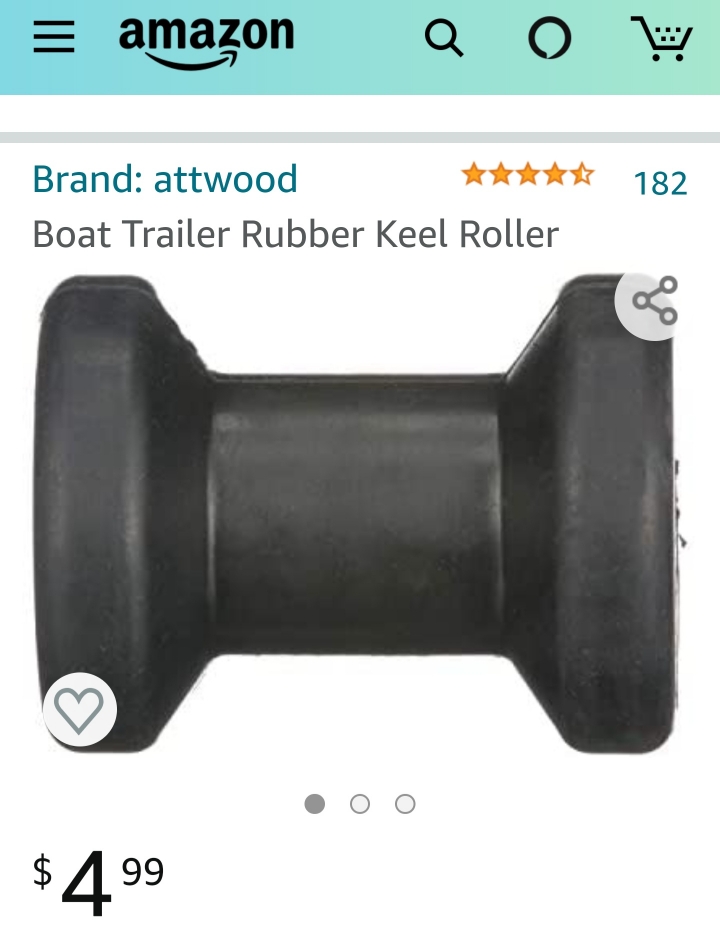

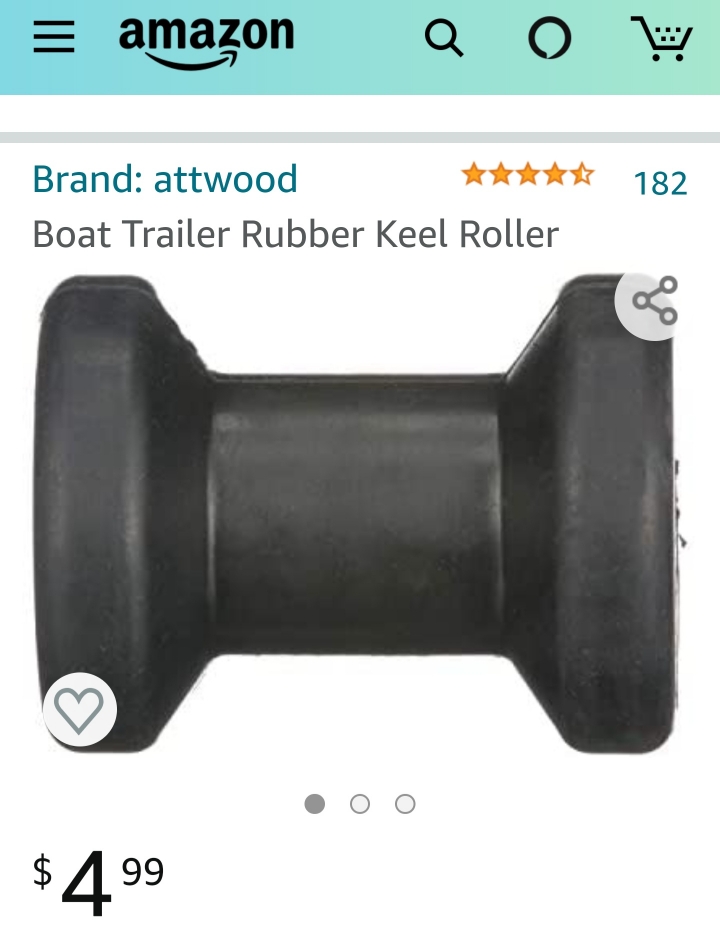

I bought a boat winch and two rollers on Amazon for $45.93. Now the question is how to stick this stuff together that it works. I drilled the I-beam to attach a roller, but then I headed back to the drawing board. I am now in the process of making two sliding brackets that can be tightened anywhere along the length of the beam to lift two deer at a time. In my theory three or four deer could be hung at a time and skinned outside then rolled inside to cut up, or lifted onto the back of a pickup. I plan on finding out soon if this works, or if it's a Rube Goldberg idea.

DocHolladay

Well-Known Member

I bought a boat winch and two rollers on Amazon for $45.93. Now the question is how to stick this stuff together that it works. I drilled the I-beam to attach a roller, but then I headed back to the drawing board. I am now in the process of making two sliding brackets that can be tightened anywhere along the length of the beam to lift two deer at a time. In my theory three or four deer could be hung at a time and skinned outside then rolled inside to cut up, or lifted onto the back of a pickup. I plan on finding out soon if this works, or if it's a Rube Goldberg idea.

If that roller doesn’t hold up, buy a clear yellow one. They are a little more expensive, but are way tougher.

Sent from my iPhone using Tapatalk

swat1018

Well-Known Member

I would have gone with the electric winch, mounted to the I beam. I have one mounted in my butcher shop / barn kitchen. 12' ceiling. My next broject is to anchor a pulley to the floor so I can pull the hide with the winch. You could brobably put a cross member at the bottom to skin with.

Mennoniteman

Well-Known Member

Good to know. I don't expect that the roller is going to get much wear with a flat strap going over it at slower speeds with less than 300 lbs. hanging on it. I could probably have run the strap over a bolt without a roller and it would have worked ok.If that roller doesn’t hold up, buy a clear yellow one. They are a little more expensive, but are way tougher.

Sent from my iPhone using Tapatalk

I was considering a power winch, and I might still add one later. The one thing that I wanted was to not have any batteries to charge or cords to drag along when I roll this thing around. Also, butchering involves spraying water, not having electric is one less thing to worry about keeping dry. And I have butchered a lot of deer by lifting them with a cable come-along winch, and the lifting part was always a minor part of the process. I'm waiting to see how this boat winch works to actually lift a deer.I would have gone with the electric winch, mounted to the I beam. I have one mounted in my butcher shop / barn kitchen. 12' ceiling. My next broject is to anchor a pulley to the floor so I can pull the hide with the winch. You could brobably put a cross member at the bottom to skin with.

I have an Aframe engine hoist I built many years ago that I took down to the deer lease that is still there. It has a boat winch on it and works great!Good to know. I don't expect that the roller is going to get much wear with a flat strap going over it at slower speeds with less than 300 lbs. hanging on it. I could probably have run the strap over a bolt without a roller and it would have worked ok.

I was considering a power winch, and I might still add one later. The one thing that I wanted was to not have any batteries to charge or cords to drag along when I roll this thing around. Also, butchering involves spraying water, not having electric is one less thing to worry about keeping dry. And I have butchered a lot of deer by lifting them with a cable come-along winch, and the lifting part was always a minor part of the process. I'm waiting to see how this boat winch works to actually lift a deer.

Native Hunter

Well-Known Member

That looks good. This is what we use:

Drycreek

Well-Known Member

I skinned and quartered my buck last Sunday while he was hanging on my tractor forks. Up or down was just three seconds away. I like it !

Three of us hunted antelope in Wyoming and the rancher was kind enough to lift our goats with his skid steer since there weren’t any trees around. That worked well too.

That worked well too.

(this is just an unashamed excuse to show off my goat !)

Three of us hunted antelope in Wyoming and the rancher was kind enough to lift our goats with his skid steer since there weren’t any trees around.

(this is just an unashamed excuse to show off my goat !)

That’s what I use here at home...lolThat looks good. This is what we use:

Mennoniteman

Well-Known Member

I use my FEL sometimes, but if someone gets a deer right ar quitting time and I'm in a hurry to get it quartered and in an icechest, getting the tractor out of the shed, jumping on and off the tractor several times to lift up another foot, then locking the tractor back into the shed seems to take a lot of time. Because of CWD regulations we can't throw our deer on the back of a pickup truck and take them with. All spinal cord tissue has to stay in that area. So my goal is a dedicated hoist ready to lift without any preparation.That’s what I use here at home...lol

Allen

Sent from my SM-G965U using Tapatalk

Mennoniteman

Well-Known Member

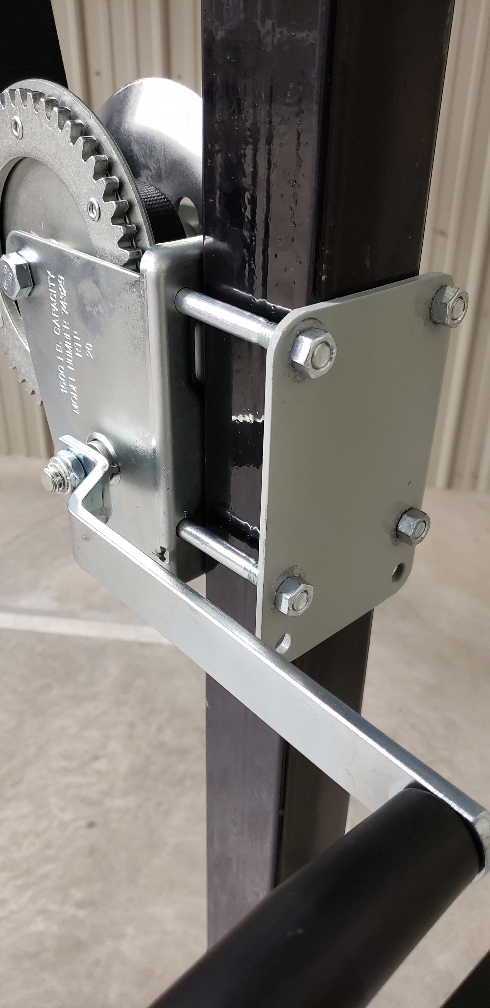

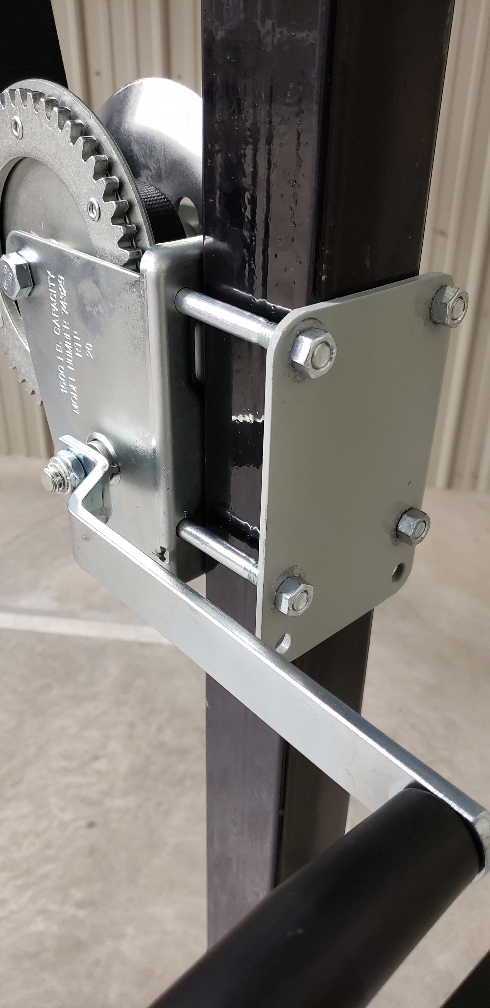

Got the winch on my deer hoist. Drilled 4 new 3/8" dia. holes in the boat winch to get 4-3/8" X 3" bolts past the side post tubing, because the post has an insert, so I can't bolt through the middle of the post, and made a backer plate out of 3/16" steel plate to match the holes that are 3" oc. wide and 4" oc. high, added in inch of extra height to the backer plate with two more holes to add hooks to hang my meat saw on.

Mennoniteman

Well-Known Member

I got to thinking, something about your boat winch comment rings a bell. I'm starting to remember that I got the idea to use a boat winch from you in the first place, from another deer hoist thread. Thanks for your contribution to my project.I have an Aframe engine hoist I built many years ago that I took down to the deer lease that is still there. It has a boat winch on it and works great!

Allen

Mennoniteman

Well-Known Member

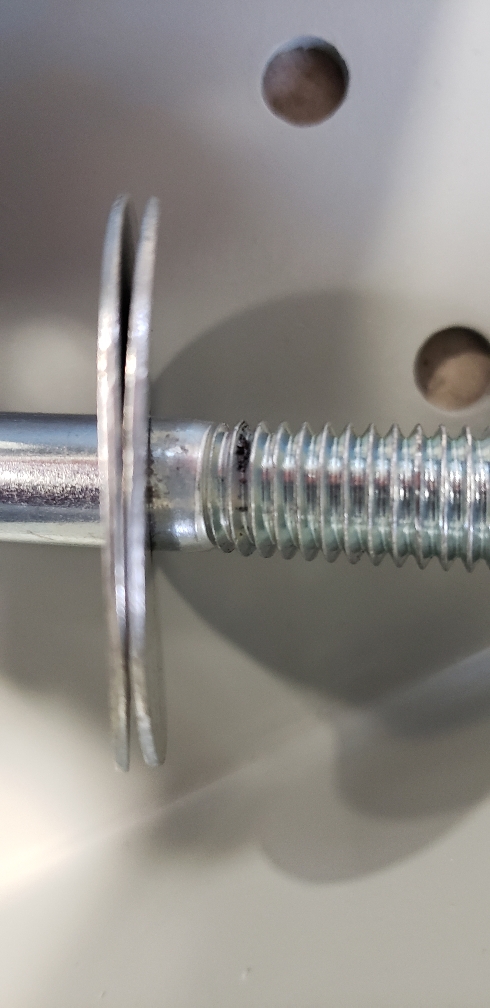

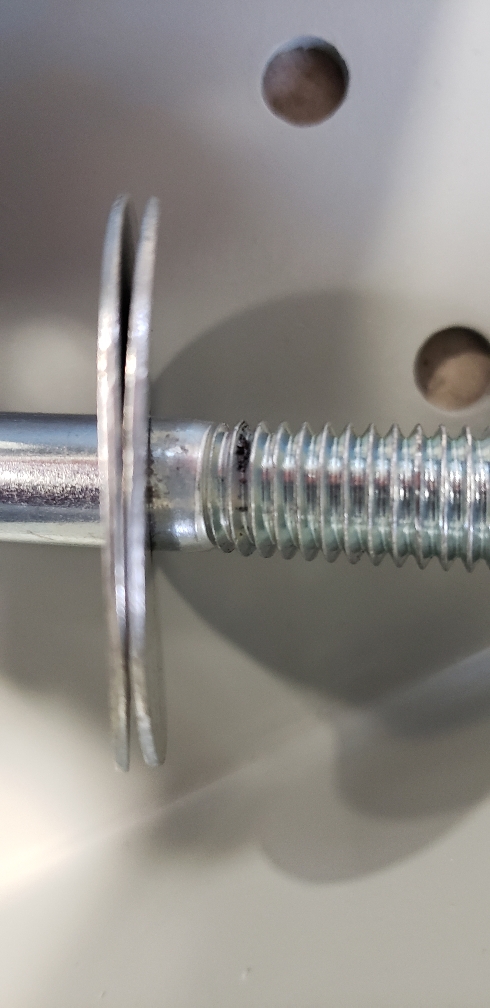

I finished the hoist yesterday. I got very thin flat washers and put a slight bend in them to act as a slight brake and keep the rollers from free wheeling.

Mennoniteman

Well-Known Member

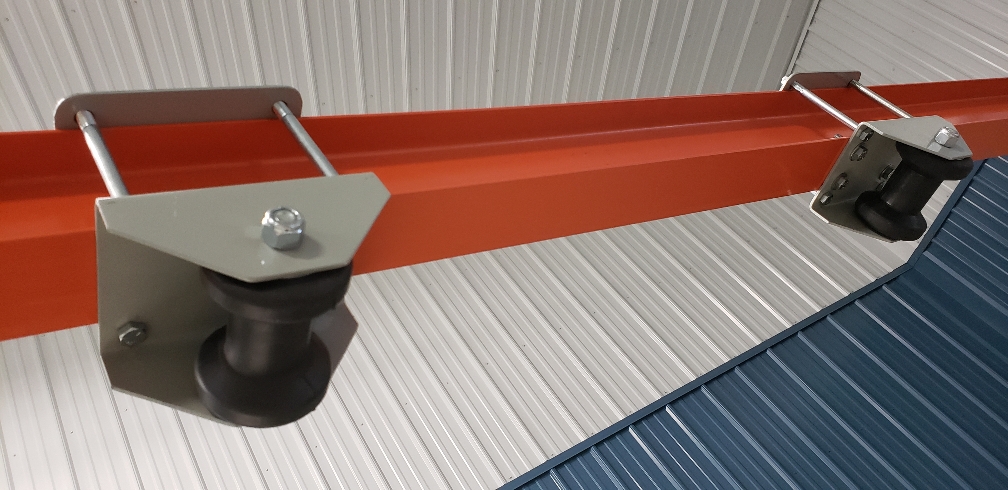

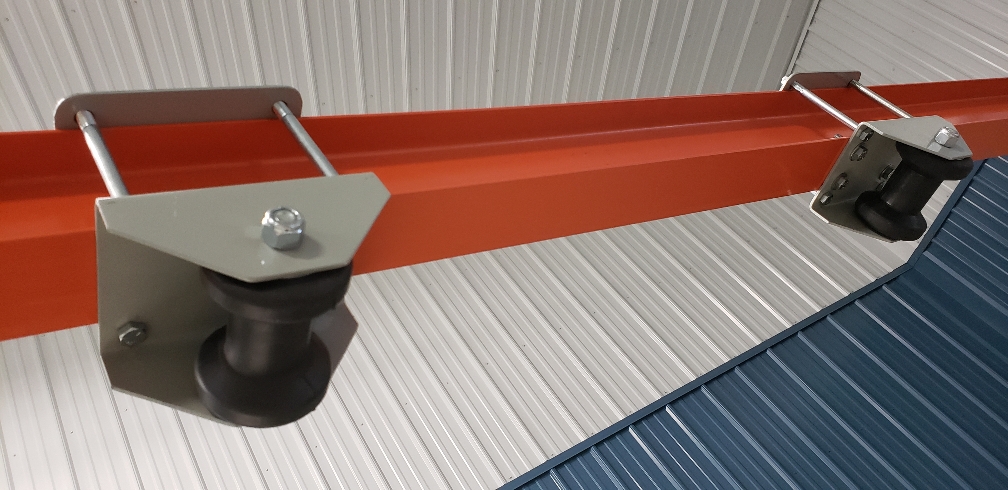

When I build something it's usually a bit overkill. These rollers are built to last until the Lord returns.

Mennoniteman

Well-Known Member

My idea of making the bracket positions adjustable seems to be working out well.

Mennoniteman

Well-Known Member

I had some junior hunters out shooting their first deer and so I had three deer to skin quarter, and get into icechests in a minimal amount of time. Forticiously I had just finished the new hoist and it made all the difference in speeding up the process. The boat winch works even better than a power winch when you have a willing hunter cranking it for you, and it is so high- tech it even works on voice commands.

I put two wheels out over the edge of my concrete pad so the rolling away part was not an issue, now I still have to test it inside to see if it want to roll while I am skinning. The unit was very stable, not top heavy or swaying a all with a deer swinging by the strap. However, none of the deer were 200 lbs either.

All in all, I consider this thing is a big success to fill a need that we had for a quick, portable deer lifting solution, which I attribute mostly to ideas that I gleaned from this forum.

Someone could probably build a similar one from scrap steel and not be spending the $500 plus that I got into it, but it's worth every penny to me.

I put two wheels out over the edge of my concrete pad so the rolling away part was not an issue, now I still have to test it inside to see if it want to roll while I am skinning. The unit was very stable, not top heavy or swaying a all with a deer swinging by the strap. However, none of the deer were 200 lbs either.

All in all, I consider this thing is a big success to fill a need that we had for a quick, portable deer lifting solution, which I attribute mostly to ideas that I gleaned from this forum.

Someone could probably build a similar one from scrap steel and not be spending the $500 plus that I got into it, but it's worth every penny to me.

Last edited:

Similar threads

- Replies

- 0

- Views

- 2K

- Replies

- 2

- Views

- 2K