Drycreek

Well-Known Member

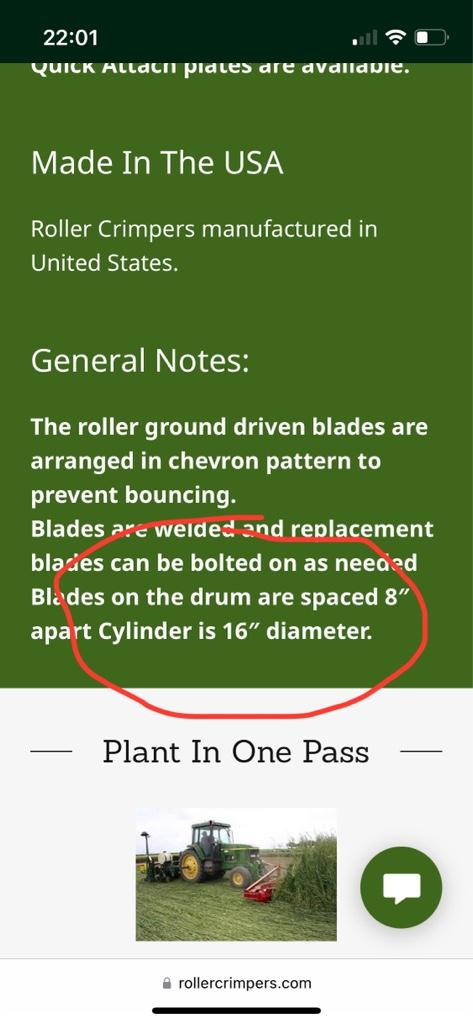

I’m about to convert a roller into a crimper, actually a drag roller into a three point crimper. I have a good friend who is a great welder/fabricator so I have that part handled. My question is; how far apart do the “fins” need to be on the drum ?

I put this in the food plot subforum because I figured it would get more attention from someone who can answer this. If it needs to be moved, admins feel free to do so.

I put this in the food plot subforum because I figured it would get more attention from someone who can answer this. If it needs to be moved, admins feel free to do so.