-

The forum has been upgraded to support both light and dark themes. Click here for directions.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

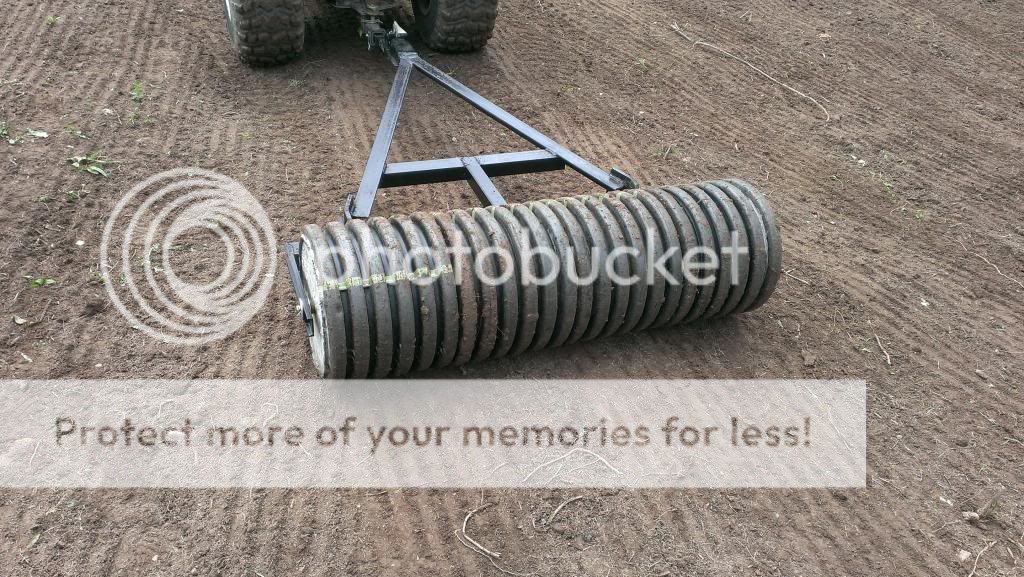

Cultipacker

- Thread starter JohnL48

- Start date

wbpdeer

Well-Known Member

JohnL

I admire your cultipacker build. This is exactly the type of post that helps people - well illustrated and gives others the motivation to try.

I have a 4 ft cultipacker that I purchased. At first I thought it was too little but it allows me to get into a field sooner because the 4 wheeler and it don't struggle in damp ground. It is highly maneuverable too.

Thanks for sharing.

I admire your cultipacker build. This is exactly the type of post that helps people - well illustrated and gives others the motivation to try.

I have a 4 ft cultipacker that I purchased. At first I thought it was too little but it allows me to get into a field sooner because the 4 wheeler and it don't struggle in damp ground. It is highly maneuverable too.

Thanks for sharing.

JohnL48

Well-Known Member

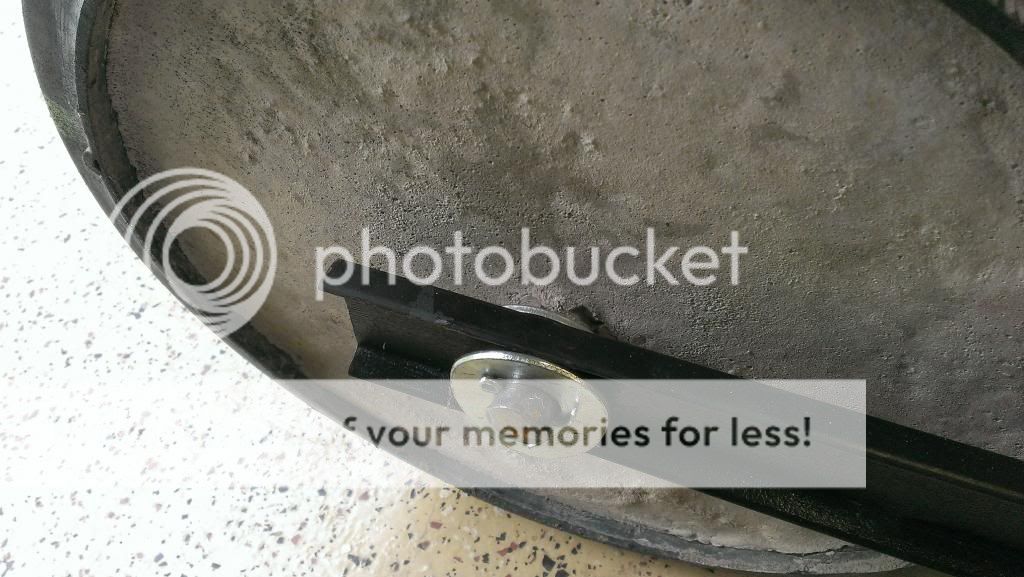

I used a 3/4" solid rodWhat did you actually use for your axle? I have a galvanized pipe, but yours appears to run solid.

Twolftg

Active Member

So do you have a hollow pipe it runs through? How did you attach the 1ft sections together?I used a 3/4" solid rod

GonHuntin

Active Member

John

This is by far the best plastic drain pipe cultipacker build I have ever seen. I especially like the "built in 4 sections" aspect and the groove cleaners......very well thought out.

I assume you filled the drain pipe with cement?? How did you make certain that the cement completely filled the ridges in the pipe?? I always figured any hollow areas in the ridges would eventually break out.

I briefly worked for a company that did refractory work and we used concrete vibrators to assure that the refractory material completely filled all areas of the vessel, but I doubt most folks have access to a concrete vibrator??

This is by far the best plastic drain pipe cultipacker build I have ever seen. I especially like the "built in 4 sections" aspect and the groove cleaners......very well thought out.

I assume you filled the drain pipe with cement?? How did you make certain that the cement completely filled the ridges in the pipe?? I always figured any hollow areas in the ridges would eventually break out.

I briefly worked for a company that did refractory work and we used concrete vibrators to assure that the refractory material completely filled all areas of the vessel, but I doubt most folks have access to a concrete vibrator??

Twolftg

Active Member

In mine I made the concrete a little on the loose side and just tapped it with a hammer but I made mine 4ft solid. I didn't have access to a welder at the time but my bolt togther frame is getting the job done.John

This is by far the best plastic drain pipe cultipacker build I have ever seen. I especially like the "built in 4 sections" aspect and the groove cleaners......very well thought out.

I assume you filled the drain pipe with cement?? How did you make certain that the cement completely filled the ridges in the pipe?? I always figured any hollow areas in the ridges would eventually break out.

I briefly worked for a company that did refractory work and we used concrete vibrators to assure that the refractory material completely filled all areas of the vessel, but I doubt most folks have access to a concrete vibrator??

JohnL48

Well-Known Member

I used larger pipe in the small sections with bolts welded to them so they wouldn't spin. The inside of this pipe was smooth. So no worries about the cement filling the ridges. The pipe in the sections acted as a sleeve for the solid rod. I'll dig up more pics tonight

Sent from my SM-G920V using Tapatalk

Sent from my SM-G920V using Tapatalk

GonHuntin

Active Member

Are you saying the inside of the plastic pipe is smooth? Are the ridges hollow?? If so, how long do you think it will last before the plastic in the hollow ridges breaks and comes apart?

I have an old cultipacker with hollow cast iron wheels and I have one broken wheel due to rocks........can't imagine a hollow plastic ridge would last even one year on my ground.

I have an old cultipacker with hollow cast iron wheels and I have one broken wheel due to rocks........can't imagine a hollow plastic ridge would last even one year on my ground.

JohnL48

Well-Known Member

Yes, its double walled and very strong. been using it for a few years without a single issue. I don't drag race with it.Are you saying the inside of the plastic pipe is smooth? Are the ridges hollow?? If so, how long do you think it will last before the plastic in the hollow ridges breaks and comes apart?

I have an old cultipacker with hollow cast iron wheels and I have one broken wheel due to rocks........can't imagine a hollow plastic ridge would last even one year on my ground.

Last edited:

Twolftg

Active Member

Are you saying the inside of the plastic pipe is smooth? Are the ridges hollow?? If so, how long do you think it will last before the plastic in the hollow ridges breaks and comes apart?

I have an old cultipacker with hollow cast iron wheels and I have one broken wheel due to rocks........can't imagine a hollow plastic ridge would last even one year on my ground.

I bought the single wall culvert because I figure there is no point in having double wall with it concrete. Obviously there is no 100% way to know the ridges are full, but they all sound full and I made my concrete loose enough to fill. Here is mine.