E_308

Well-Known Member

Had to move this one over more for my records than anything else.

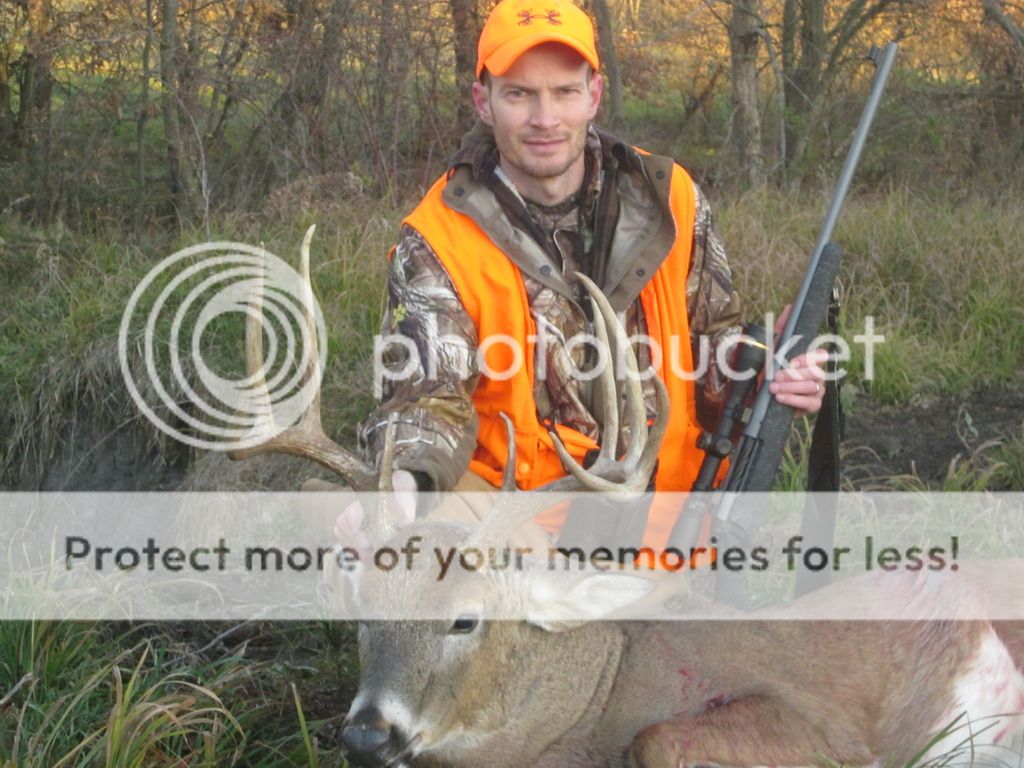

I have decided to put together a rifle based on a Remington 700 30-06 my Dad bought back in the early 80's. The plan is to come up with a rifle that can handle all the hunting I can afford to do. It will stay an 06' because every small town gun shop and general stores will have something to feed it, worldwide anywhere big game is hunted. It is no secret that I think the 308 is the perfect deer rifle. That said the 06 is better with the heavier bullets for larger game. I will never hunt the big bears - the 06 can handle everything else on this continent. I hope to make it to Africa some day, with some good 180 grain bullets it will also handle the reach of my checkbook. I know some will say a magnum would be better. I have a 300 win mag gathering dust in the cabinet. Heavy, loud, and expensive to shoot. The 30-06 has been every where in it's almost 110 years in service.

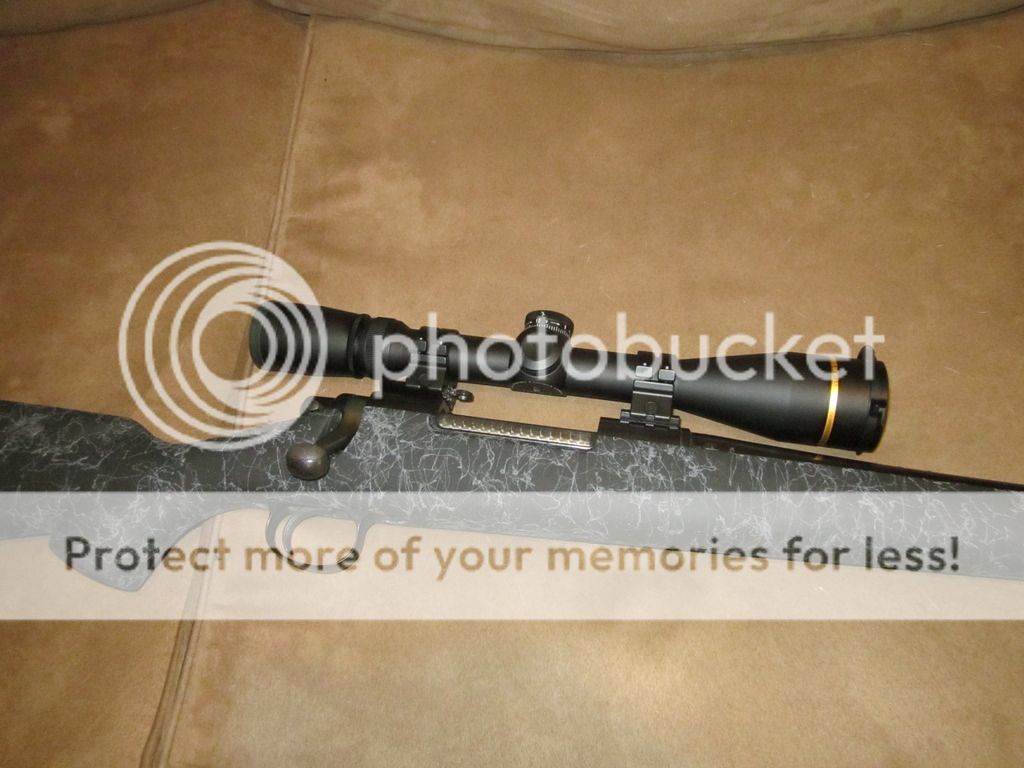

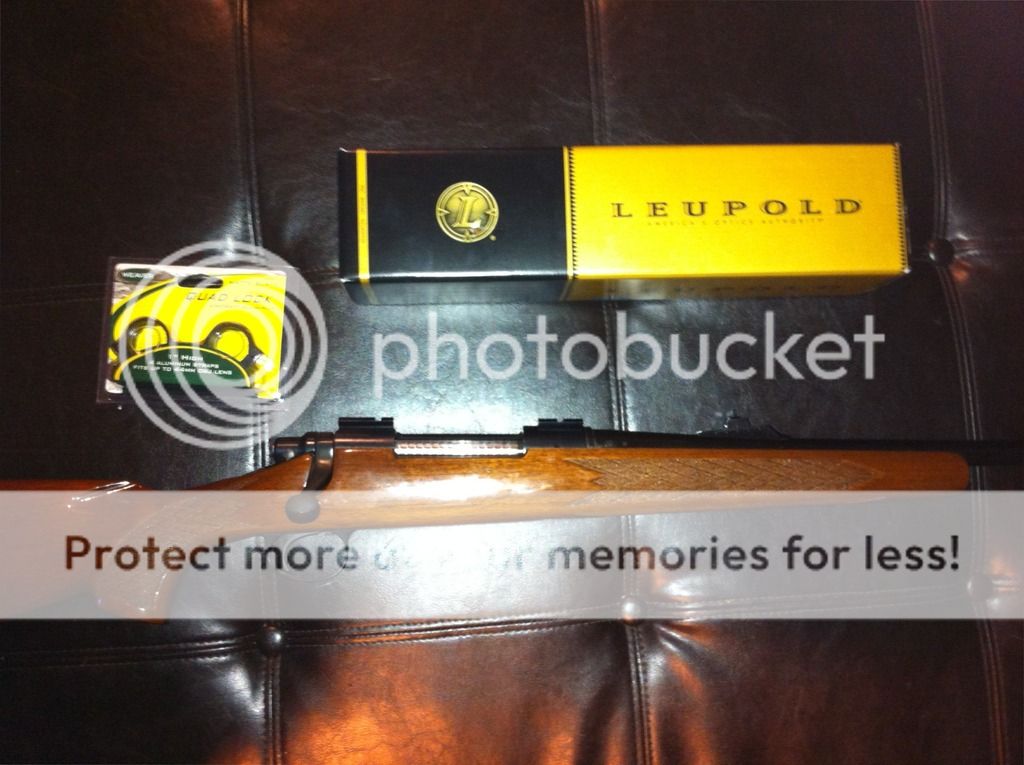

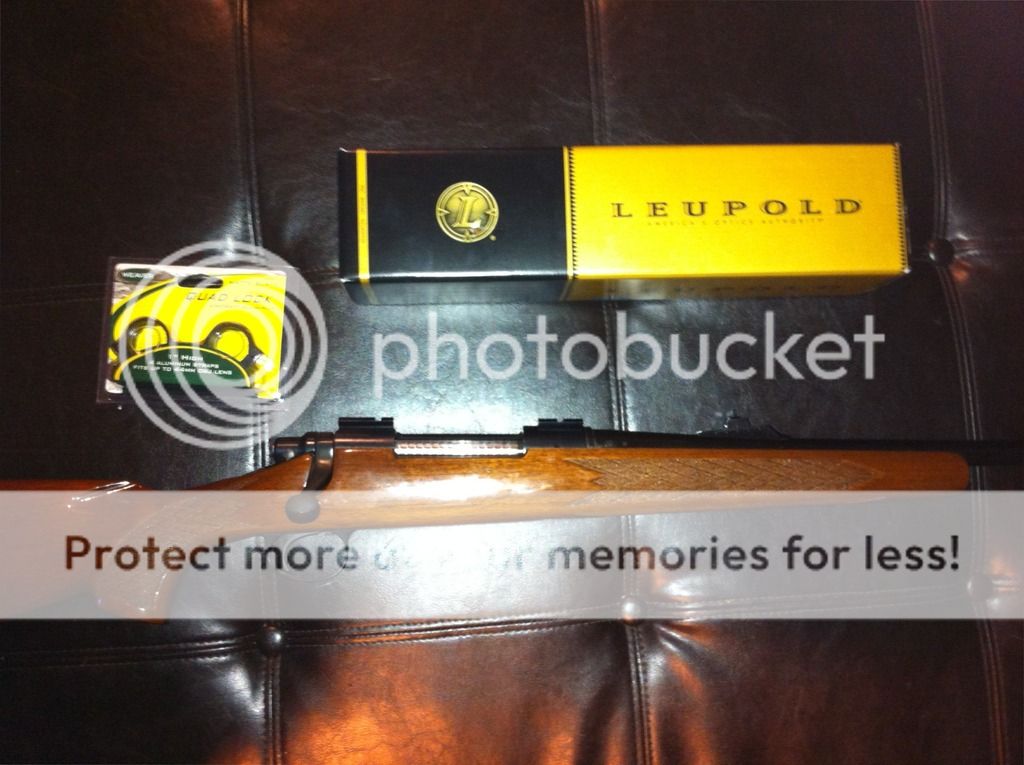

Step one = glass. I am leaving the iron sights on, knowing I will probably never use them. The option will always be there. I choose simple, strong, and light Weaver rings. Requirement here is they had to tighten with a standard flat head screwdriver (always with me on the leatherman). So many rings today attach with allen heads. I also have a backup burris scope mounted in another set of rings (probably never need it either). The main scope is a Leupold VX III with the CDS reticle. I will have the initial dial calibrated for a 165 grain bullet of some sort once I get a load worked up.

One complication with the irons is I can't use my regular flip up scope caps. Going to have to start researching alternatives.

Still to come:

stock - staying with the ADL so limited on choices in the $200-300 range leaning towards HS precision

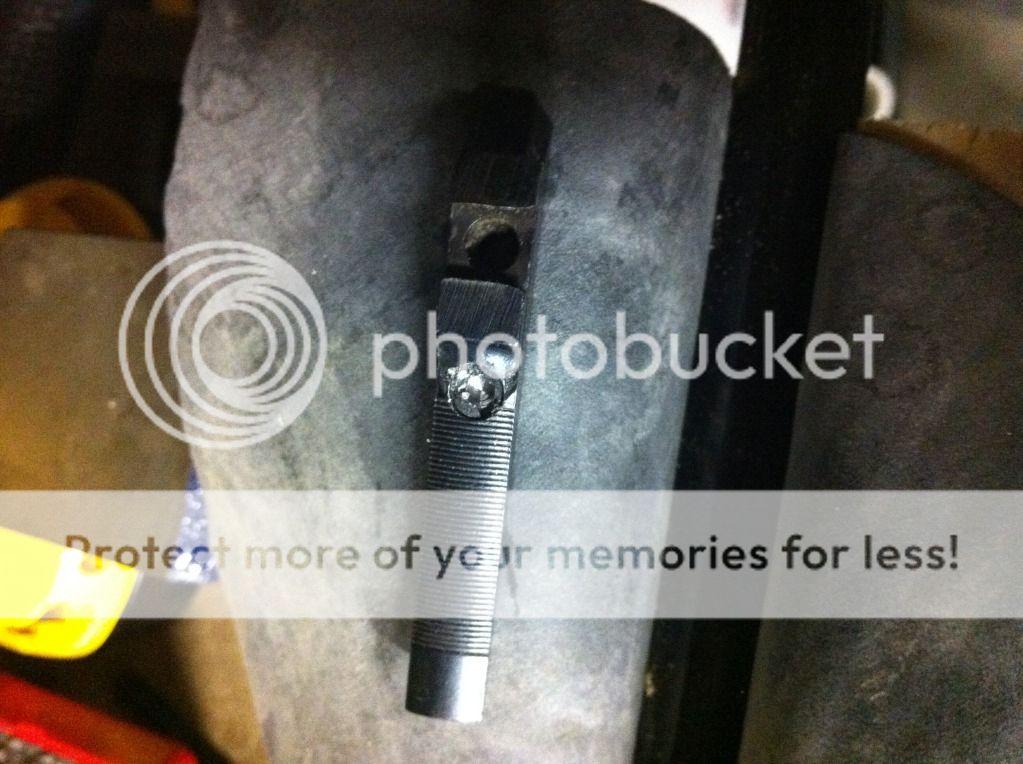

Fluting - bolt

Cerakote - metal

Trigger upgrade - currently has the old one that locks the bolt on safe

Should be a fun project with some good sentimental value. If any of you know my wife don't put a price tag on any of this! Or that we all know why "need" is in parenthesis!

I have decided to put together a rifle based on a Remington 700 30-06 my Dad bought back in the early 80's. The plan is to come up with a rifle that can handle all the hunting I can afford to do. It will stay an 06' because every small town gun shop and general stores will have something to feed it, worldwide anywhere big game is hunted. It is no secret that I think the 308 is the perfect deer rifle. That said the 06 is better with the heavier bullets for larger game. I will never hunt the big bears - the 06 can handle everything else on this continent. I hope to make it to Africa some day, with some good 180 grain bullets it will also handle the reach of my checkbook. I know some will say a magnum would be better. I have a 300 win mag gathering dust in the cabinet. Heavy, loud, and expensive to shoot. The 30-06 has been every where in it's almost 110 years in service.

Step one = glass. I am leaving the iron sights on, knowing I will probably never use them. The option will always be there. I choose simple, strong, and light Weaver rings. Requirement here is they had to tighten with a standard flat head screwdriver (always with me on the leatherman). So many rings today attach with allen heads. I also have a backup burris scope mounted in another set of rings (probably never need it either). The main scope is a Leupold VX III with the CDS reticle. I will have the initial dial calibrated for a 165 grain bullet of some sort once I get a load worked up.

One complication with the irons is I can't use my regular flip up scope caps. Going to have to start researching alternatives.

Still to come:

stock - staying with the ADL so limited on choices in the $200-300 range leaning towards HS precision

Fluting - bolt

Cerakote - metal

Trigger upgrade - currently has the old one that locks the bolt on safe

Should be a fun project with some good sentimental value. If any of you know my wife don't put a price tag on any of this! Or that we all know why "need" is in parenthesis!