bigbluetruck

Active Member

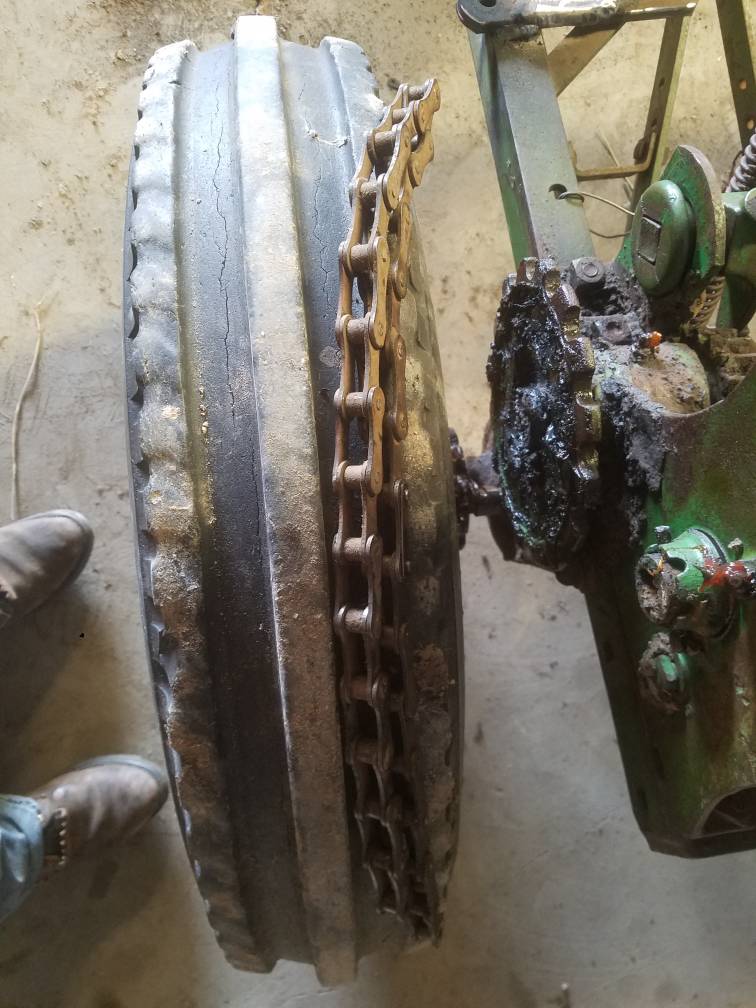

Here's where I'm going to document my build of an ATV drill out of a 11ft John Deere Van Brunt "B" drill.

I picked up 2 of these on a sale last fall and now that crops are in, fertilized and cows are to pasture I have a little more time in between irrigating and making hay.

Both are in good shape, havent been used in a few years but stored inside so that helps. This one is getting cut in half to make 2 drills, it's really a fairly simple process. The other is going to be made into a 11ft 3pt drill.

Turns out, if you take the hitch off, you need to block up the back end or it will tip over, luckily no one or the drill was hurt!

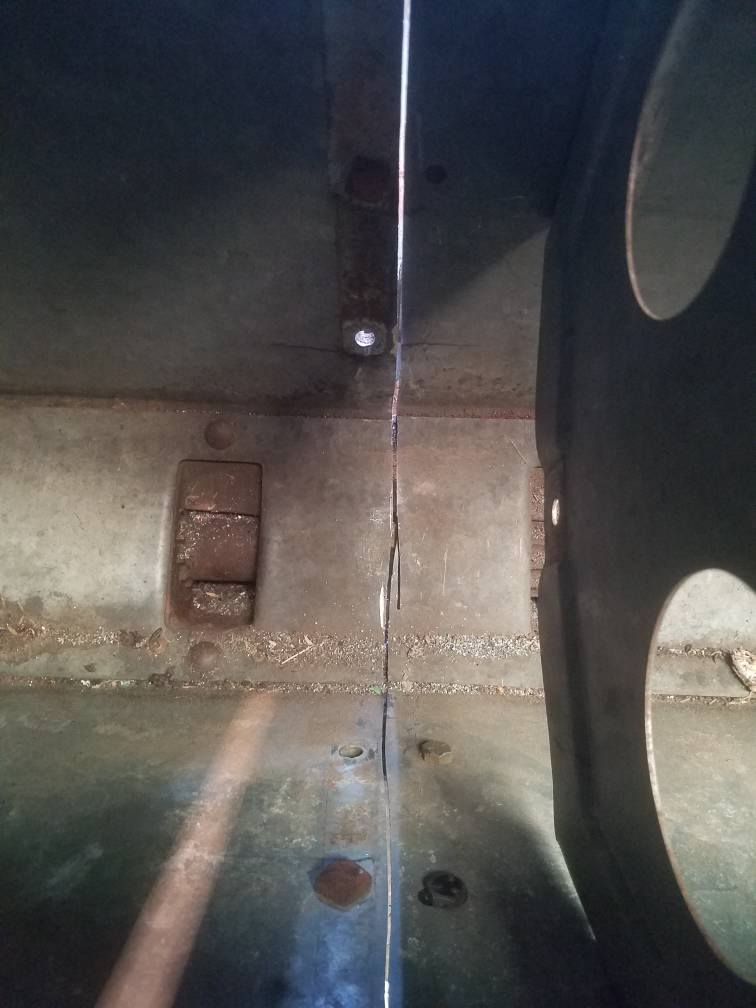

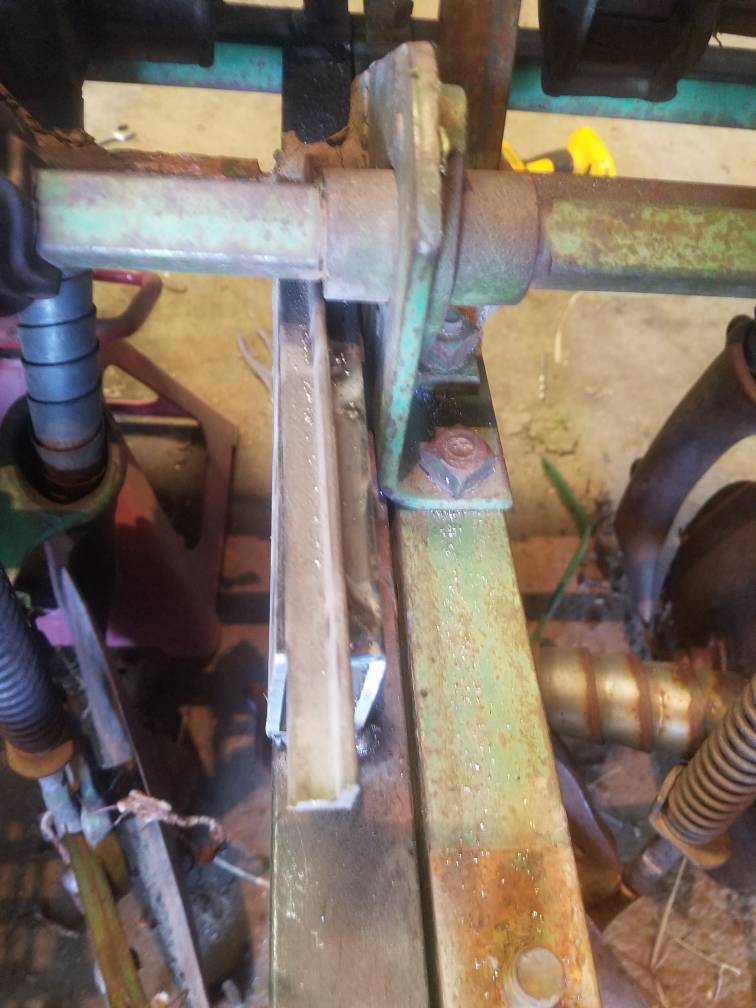

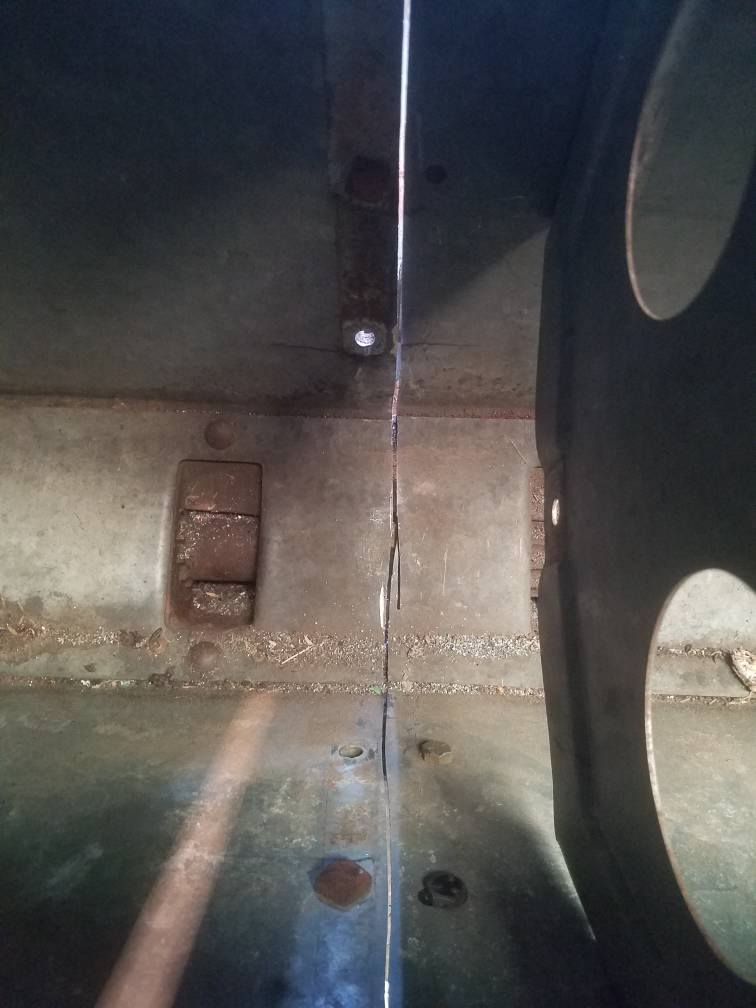

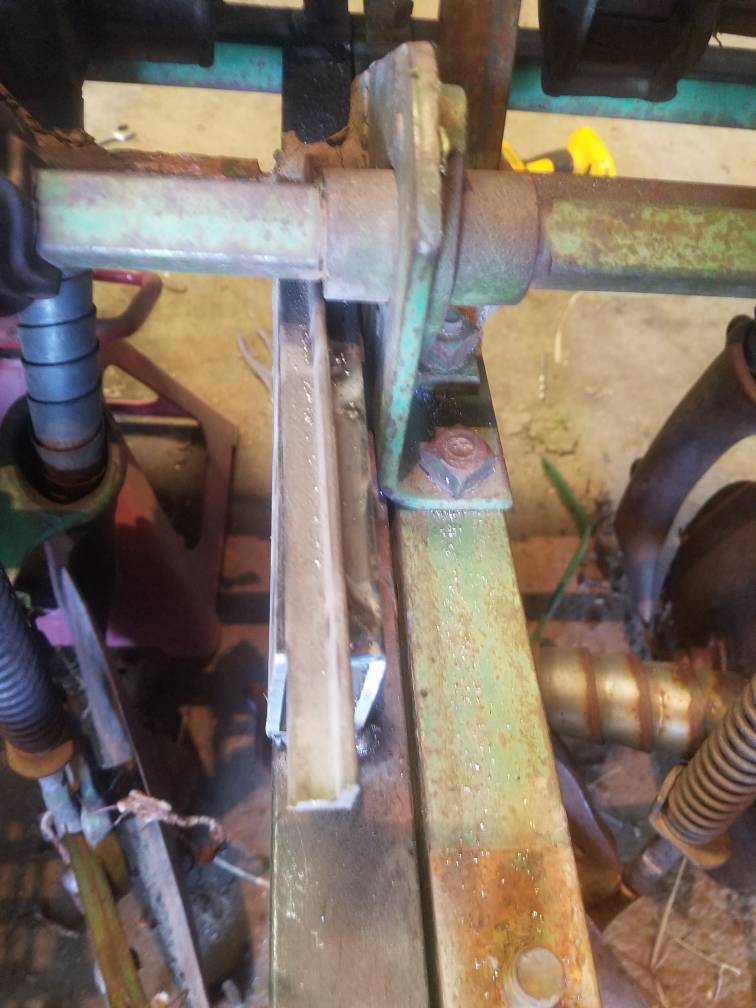

Got the box cut in half, the left side of the right side frame angle in, and everything blocked up ready to split after I cut

Sent from my SM-G930V using Tapatalk

I picked up 2 of these on a sale last fall and now that crops are in, fertilized and cows are to pasture I have a little more time in between irrigating and making hay.

Both are in good shape, havent been used in a few years but stored inside so that helps. This one is getting cut in half to make 2 drills, it's really a fairly simple process. The other is going to be made into a 11ft 3pt drill.

Turns out, if you take the hitch off, you need to block up the back end or it will tip over, luckily no one or the drill was hurt!

Got the box cut in half, the left side of the right side frame angle in, and everything blocked up ready to split after I cut

Sent from my SM-G930V using Tapatalk