David

Active Member

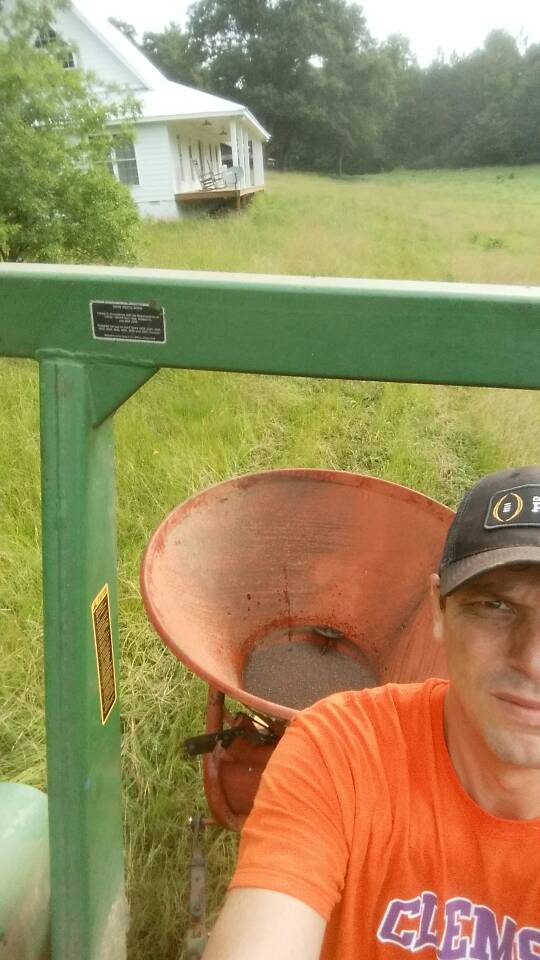

I have yet to use the spreader attachment for my tractor. I have been too nervous about putting 900 lbs of fertilizer and going at it. The previous owner told me the two times he used it that he was unable to controll the flow and it spread the entire load in under a minute.

Regardless I am going to test it with sand, so here are my two questions.

1) any helpful tips?

2) what ever you call the spinner/agitator that is in the bottom of the bucket and keeps the fertilzer/seed flowing is absolutely HUGE. Seems to me it would break in one turn if it was under 900 lbs of sand or fertilzer. Usually I see them and they are maybe a large Cotter pin....1-3 inches. This thing is a big wheel on the end of a 8 inch shaft. Any reason I should fear this thing snapping?

It's a king cutter.

Sent from my SM-G900V using Tapatalk

Regardless I am going to test it with sand, so here are my two questions.

1) any helpful tips?

2) what ever you call the spinner/agitator that is in the bottom of the bucket and keeps the fertilzer/seed flowing is absolutely HUGE. Seems to me it would break in one turn if it was under 900 lbs of sand or fertilzer. Usually I see them and they are maybe a large Cotter pin....1-3 inches. This thing is a big wheel on the end of a 8 inch shaft. Any reason I should fear this thing snapping?

It's a king cutter.

Sent from my SM-G900V using Tapatalk