j-bird

Well-Known Member

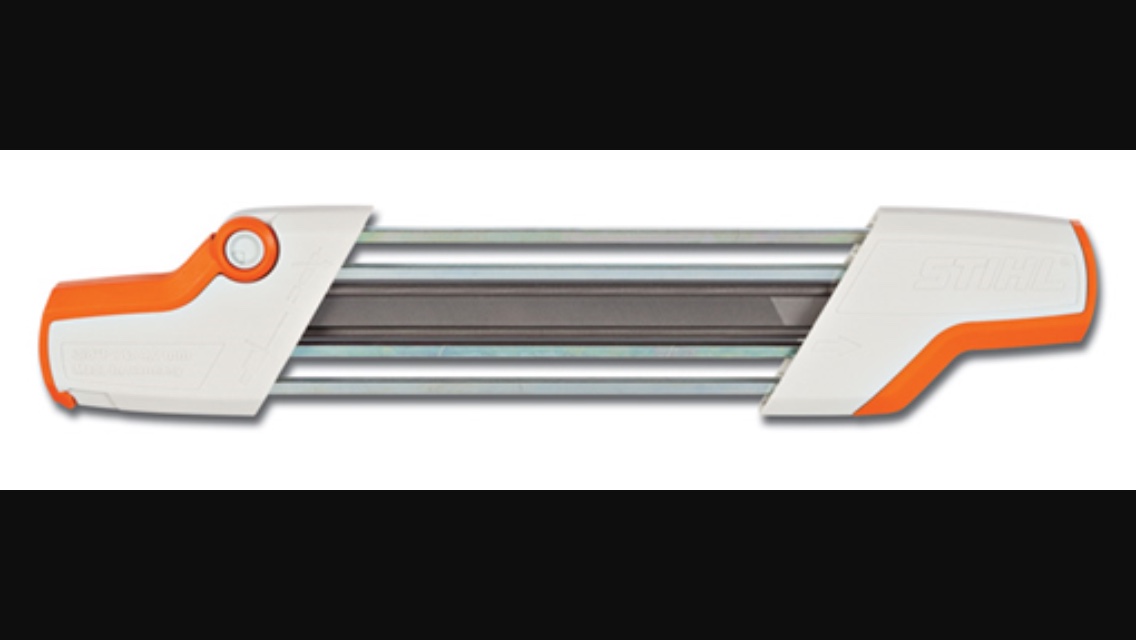

For those of you who sharpen your own saw chains - which bench top tool works best?

I use a round file in the woods, but sometimes you just need to bite the bullet and truly sharpen the chain. I'm looking for a means to do this without going broke in the process. I'm figuring a bench top electric unit in the $100 to $200 should do just fine, but I don;t want to be replacing this every year either. I only need something to do maybe a dozen chains all winter at most. I just hate having to pay someone to do it and then they heat the teeth up too much and ruin them in the process! Anybody have experience with these sort or have any suggestions?

I use a round file in the woods, but sometimes you just need to bite the bullet and truly sharpen the chain. I'm looking for a means to do this without going broke in the process. I'm figuring a bench top electric unit in the $100 to $200 should do just fine, but I don;t want to be replacing this every year either. I only need something to do maybe a dozen chains all winter at most. I just hate having to pay someone to do it and then they heat the teeth up too much and ruin them in the process! Anybody have experience with these sort or have any suggestions?