yoderjac

Well-Known Member

I have a somewhat unique situation. I have a barn with a cement floor that use as a deer blind from time to time. A year or so ago, I stopped growing trees from nuts, so I converted one of my watering tub holders into a shooting bench. It was just 2x4 structure on a harbor freight dolly that supported a plastic Rubbermaid type tub. I just pulled the tub out and put a board over the top to make a bench top. It was too low, so stacked some 6x6 scraps near the front and put my bulls-bag on it. That worked OK, but it is not completely square so it can be a little wobbly. Functionally it works pretty well and I shot a number of deer from it, but I don't like the wobble and noise.

I think the issue is the HF dolly has warped a bit over time. My first thought was simply to remove the dolly and put casters on it. However, I'm learning to weld, and I thought this might be a good project for that. So, I'm designing a shooting bench specifically for this setup.

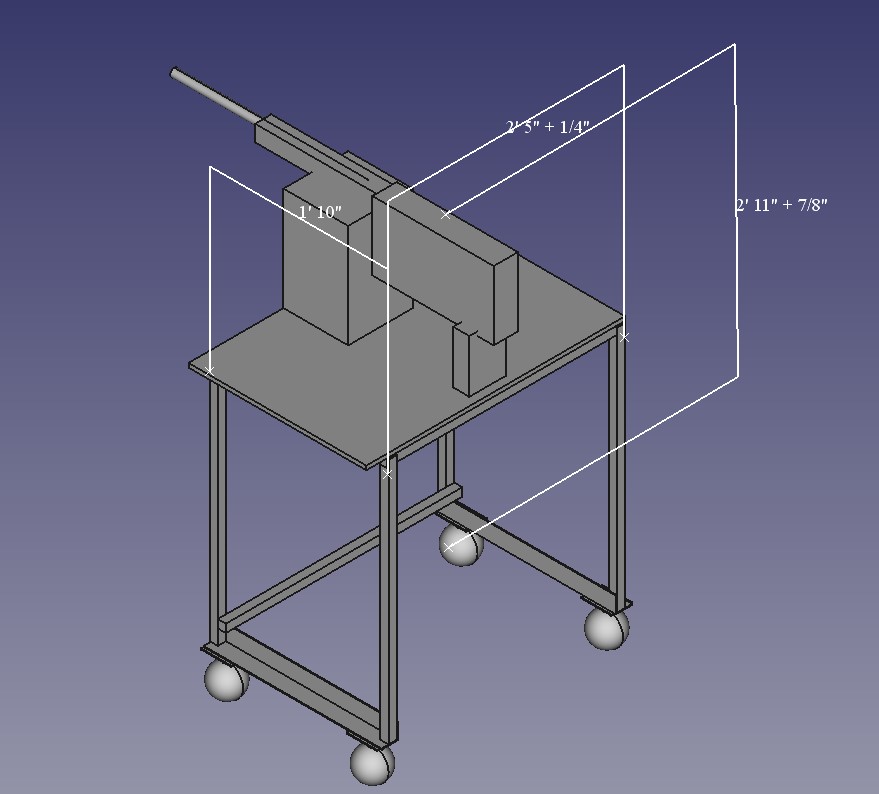

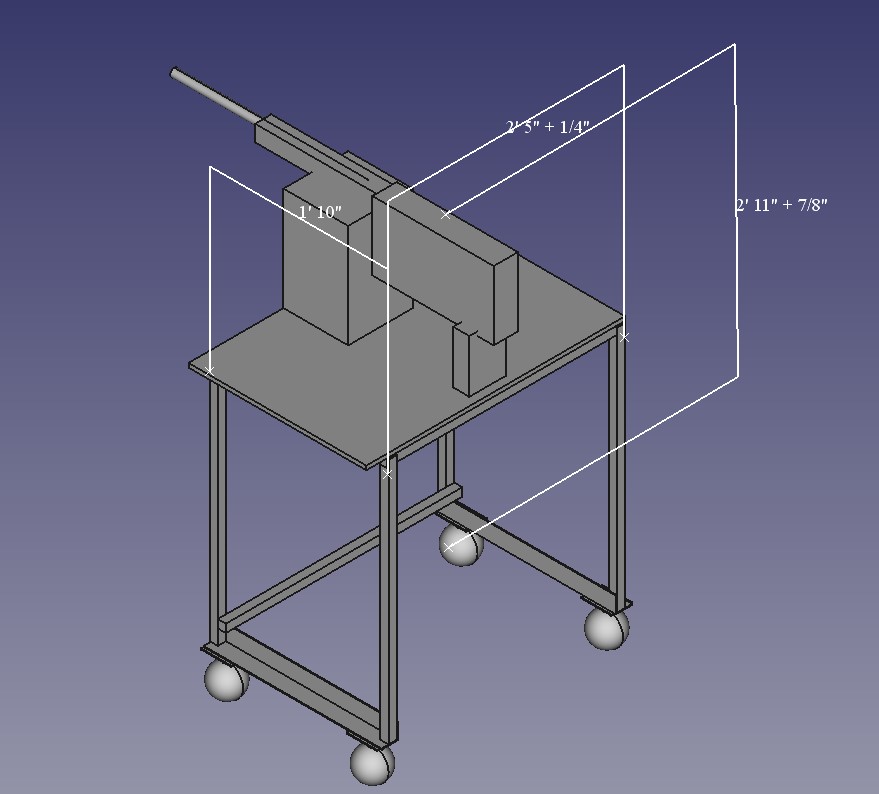

So, here is my plan up for critique and suggestions. It starts with nice 4" casters at the bottom. I've used these before and they are quiet and smooth. The bottom side braces are 2x2x22 in angle iron. Why? Just because I have a piece of scrap I can cut to this size. I also have 10 pieces of 1x1x30.5 square tubing. It was mis-cut for a custom-r so I got it cheap. So, I figured they would make good legs. I'll cut a piece of the 1x1 tubing for a lower rear cross brace. I'm using 1x1 inch angle iron to form the top. I'll drill holes in it before I weld it so I can attach a board for a bench top. Notice the bench top sticks out a few inches on the left side. I'll drill some holes in it for a ram rod and cleaning rods and such. I like to run a dry patch through my SML between shots and a Shotgun cleaning rod works good for that.

I ordered an 8x8 lab jack. It adjusts from 3"-13". I plan to put my bulls bag on it. I plan to use a 6.5" squeeze bag for the rear. The lab jack has enough adjustability for me to make any size squeeze bag work well. Once adjusted, I'll leave the lab jack fixed.

I'll hang some camo material or something on the front to help disguise any movement.

Any critique or suggestions are welcome before I get started with this project.

I think the issue is the HF dolly has warped a bit over time. My first thought was simply to remove the dolly and put casters on it. However, I'm learning to weld, and I thought this might be a good project for that. So, I'm designing a shooting bench specifically for this setup.

So, here is my plan up for critique and suggestions. It starts with nice 4" casters at the bottom. I've used these before and they are quiet and smooth. The bottom side braces are 2x2x22 in angle iron. Why? Just because I have a piece of scrap I can cut to this size. I also have 10 pieces of 1x1x30.5 square tubing. It was mis-cut for a custom-r so I got it cheap. So, I figured they would make good legs. I'll cut a piece of the 1x1 tubing for a lower rear cross brace. I'm using 1x1 inch angle iron to form the top. I'll drill holes in it before I weld it so I can attach a board for a bench top. Notice the bench top sticks out a few inches on the left side. I'll drill some holes in it for a ram rod and cleaning rods and such. I like to run a dry patch through my SML between shots and a Shotgun cleaning rod works good for that.

I ordered an 8x8 lab jack. It adjusts from 3"-13". I plan to put my bulls bag on it. I plan to use a 6.5" squeeze bag for the rear. The lab jack has enough adjustability for me to make any size squeeze bag work well. Once adjusted, I'll leave the lab jack fixed.

I'll hang some camo material or something on the front to help disguise any movement.

Any critique or suggestions are welcome before I get started with this project.