Thanks to Brushpile’s thread, I’ve learned the importance of putting down a weed barrier to help get seedlings established. His instructions on cutting the mats has been greatly helpful - http://deerhunterforum.com/index.php?threads/the-brushpile.25/page-18#post-6159.

I’ve spent the last few evenings cutting a bunch of mats and found a few things that helped speed up the process for me. Thought I’d list them here, in case it could help someone else out:

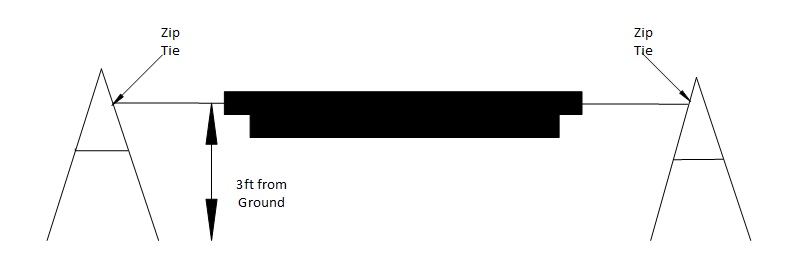

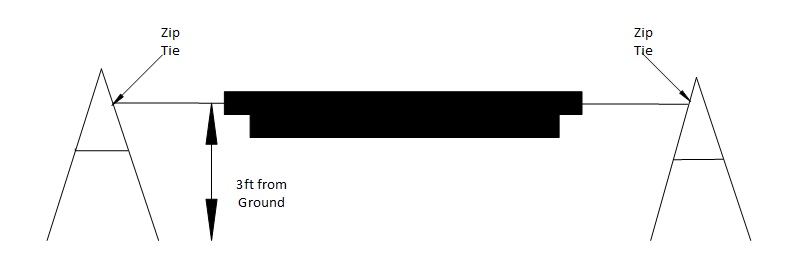

1) I used two ladders as supports to suspend the roll of Lumite. Think of a toilet paper holder. Basically, I used a 10ft section of 1 inch metallic conduit and put it through the roll of 6ft wide lumite. Then I put a ladder on each side and placed each conduit end on a ladder step around 3ft from the ground. To keep the conduit in place, I zip tied each conduit end to the corresponding ladder. This allowed me to pull the lumite off easy, and removed the resistance that I had when having to unroll off of a flat surface.

2) I used a hot knife to cut the lumite. Harbor Freight sells them for around $20 - https://www.harborfreight.com/130-watt-heavy-duty-hot-knife-60313.html. The great thing about using a hot knife is that it cuts accurately, and melts it as it goes along. I tried cutting with scissors and using a heat gun to melt on each green line, but I still had fraying. The guy from Shaw fabrics said to use a torch, but it was much harder to control and it caused the material to shrink up, not to mention that the lumite material could catch fire a bit. The hot knife was the best of both worlds.

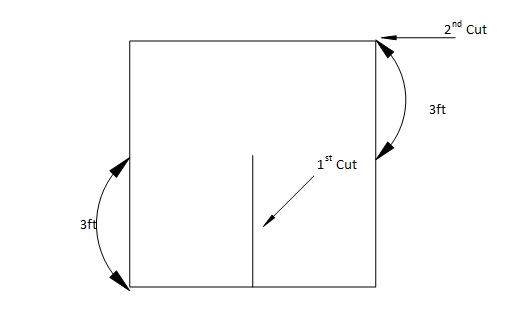

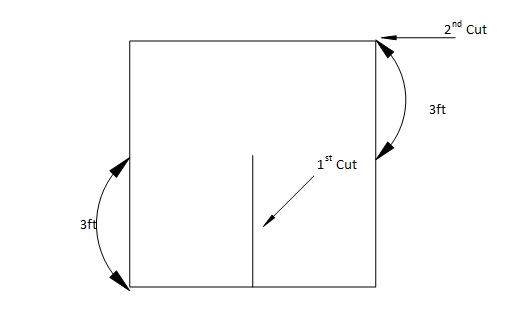

3) Being that the roll was suspended above the ground by around 3ft, I used that measurement to get my length for the midway vertical cut (see Brush’s last picture on post #352 on above link). I would make this cut first up to 3ft. Then I would use that mark for my measurement to roll out the next 3ft. At this point, I would make my horizontal cut. This allowed me to quickly measure a new 6x6 mat and make two cuts with the hot knife and move to the next mat, with no going back to make a separate measurement/cut.

These changes made it so much easier for me to cut the mats myself and it eliminated all of the fraying.

Two notes -

a) Make sure to have adequate ventilation, as the melting material will give off fumes.

b) I had to get a replacement hot knife from HF around half way through, since it quit heating up. They replaced it with no issues, and I’m guessing it was a fluke, but just FYI.

Hope this helps someone...

144

Sent from my iPhone using Tapatalk

I’ve spent the last few evenings cutting a bunch of mats and found a few things that helped speed up the process for me. Thought I’d list them here, in case it could help someone else out:

1) I used two ladders as supports to suspend the roll of Lumite. Think of a toilet paper holder. Basically, I used a 10ft section of 1 inch metallic conduit and put it through the roll of 6ft wide lumite. Then I put a ladder on each side and placed each conduit end on a ladder step around 3ft from the ground. To keep the conduit in place, I zip tied each conduit end to the corresponding ladder. This allowed me to pull the lumite off easy, and removed the resistance that I had when having to unroll off of a flat surface.

2) I used a hot knife to cut the lumite. Harbor Freight sells them for around $20 - https://www.harborfreight.com/130-watt-heavy-duty-hot-knife-60313.html. The great thing about using a hot knife is that it cuts accurately, and melts it as it goes along. I tried cutting with scissors and using a heat gun to melt on each green line, but I still had fraying. The guy from Shaw fabrics said to use a torch, but it was much harder to control and it caused the material to shrink up, not to mention that the lumite material could catch fire a bit. The hot knife was the best of both worlds.

3) Being that the roll was suspended above the ground by around 3ft, I used that measurement to get my length for the midway vertical cut (see Brush’s last picture on post #352 on above link). I would make this cut first up to 3ft. Then I would use that mark for my measurement to roll out the next 3ft. At this point, I would make my horizontal cut. This allowed me to quickly measure a new 6x6 mat and make two cuts with the hot knife and move to the next mat, with no going back to make a separate measurement/cut.

These changes made it so much easier for me to cut the mats myself and it eliminated all of the fraying.

Two notes -

a) Make sure to have adequate ventilation, as the melting material will give off fumes.

b) I had to get a replacement hot knife from HF around half way through, since it quit heating up. They replaced it with no issues, and I’m guessing it was a fluke, but just FYI.

Hope this helps someone...

144

Sent from my iPhone using Tapatalk