farmhunter

Well-Known Member

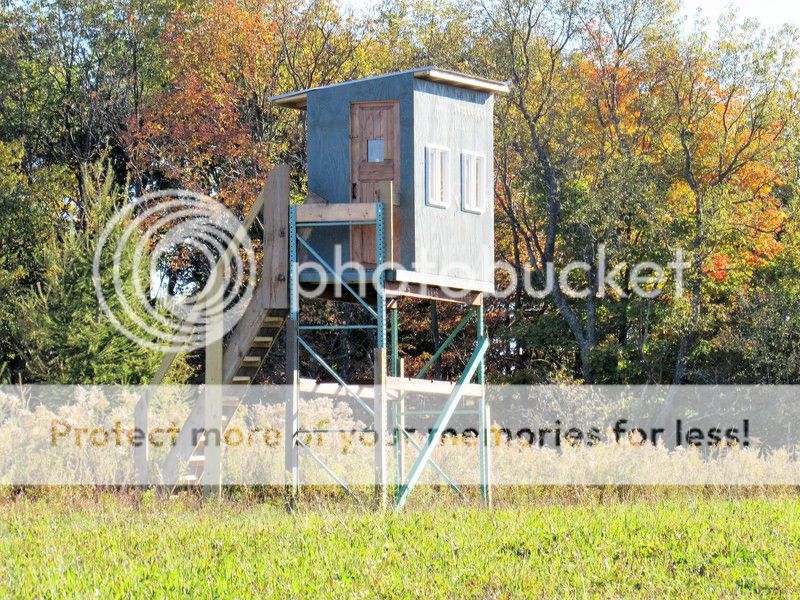

Occasionally factories will swap out their pallet racking for new ones, for various reasons - not usually because they wear out! Every so often I've been lucky enough to be able to pick up some being scrapped out. There are two ways to go about it - One is to use the steel rack- floor to ceiling in the frame - and the other is to build a box on top the platform.

The 1st box we built last fall - and we built it about 7 ft up and boxed around the frame (floor to ceiling). We cemented the feet in but did not run poles into the ground as extra support. The heavy stairs help to make sure that this tower cannot "tip over" in a big wind. This construction had advantages in that its very rigid - but the cons are that the wood is difficult to cut to fit - and gaps were inevitable - there was no prefab mfg - we had to do it all up in the air - and that has drawbacks.

Here's a look at last year's fall project.

The 1st box we built last fall - and we built it about 7 ft up and boxed around the frame (floor to ceiling). We cemented the feet in but did not run poles into the ground as extra support. The heavy stairs help to make sure that this tower cannot "tip over" in a big wind. This construction had advantages in that its very rigid - but the cons are that the wood is difficult to cut to fit - and gaps were inevitable - there was no prefab mfg - we had to do it all up in the air - and that has drawbacks.

Here's a look at last year's fall project.